FPC flexible circuit board custom manufacturing services are dedicated to meeting the individual needs of customers and providing efficient, high-quality flexible circuit board production and manufacturing.

From design to delivery, the entire process is strictly controlled to ensure the perfect combination of product performance and reliability.

Overview

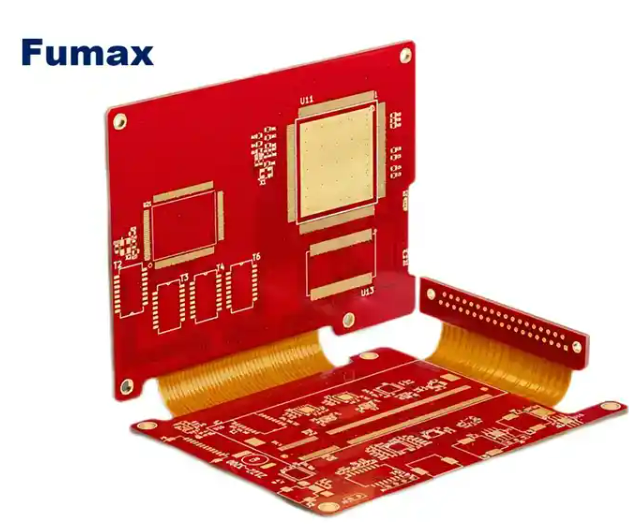

Flexible circuit board (FPC), is a printed circuit board with excellent flexibility and bendability.

It consists of flexible substrates such as polyimide or polyester and circuits made of copper foil. It is widely used in consumer electronics, medical equipment, automotive electronics and other fields.

With the continuous advancement of science and technology and the demand for miniaturization and lightweight of electronic equipment, FPC custom manufacturing services have gradually become an important production method. This article will introduce in detail the concepts, advantages, processes and other aspects of FPC flexible circuit board custom manufacturing services.

Advantages of FPC flexible circuit board custom manufacturing services

- Small batch production: As the update of electronic products accelerates, traditional rigid circuit boards cannot meet the changing market demand. FPC custom manufacturing services can quickly respond to market demand and meet customers’ small batch and diversified production needs.

- Lightweight design: FPC flexible circuit boards have excellent flexibility and bendability, which can realize lightweight design of products and help improve product portability and user experience.

- High-density wiring: FPC flexible circuit boards can achieve high-density wiring, reduce product volume, improve integration, and meet the needs of miniaturization of electronic equipment.

- High reliability: FPC flexible circuit boards adopt advanced manufacturing processes and technologies and have good electrical performance and stability, which can ensure the reliability and stability of the product.

- Strong customizability: FPC custom manufacturing services can carry out personalized design and production according to customer needs to meet customers’ special needs and customized requirements.

FPC flexible circuit board custom manufacturing service process

- Demand analysis: Conduct detailed demand analysis based on customer needs and product characteristics to determine product specifications, performance parameters and manufacturing process requirements.

- Design: Based on the demand analysis results, design the FPC flexible circuit board, including circuit design, substrate selection, layer planning, etc. Requirements such as electrical performance, mechanical performance, and reliability need to be considered during the design process.

- Manufacturing: According to the design results, the FPC flexible circuit board is manufactured. The manufacturing process includes copper foil processing, line printing, etching, film removal, electroplating and other links. Each link requires strict quality control and process parameter control.

- Assembly: After completion of manufacturing, the FPC flexible circuit board is assembled with other electronic components to form a complete electronic product. During the assembly process, care must be taken to protect the FPC flexible circuit board from damage and ensure the reliability of its electrical and mechanical properties.

- Testing and verification: After completion of assembly, comprehensive testing and verification are required to ensure that the performance parameters of the product meet the requirements and to ensure the reliability and stability of the product. Test content includes electrical performance testing, mechanical performance testing, environmental adaptability testing, etc.

- Delivery and after-sales service: After completing testing and verification, the product is delivered to the customer. At the same time, we provide comprehensive after-sales services, including technical consultation, quality assurance, repair and maintenance, etc., to meet the subsequent needs of customers.

In conclusion

With the development of electronic equipment and changes in market demand, FPC flexible circuit board custom manufacturing services have become an important production method.

It has the advantages of small batch production, lightweight design, high-density wiring, high reliability, and strong customizability, and can meet the different needs and personalized requirements of customers.

In the future, with the continuous advancement of technology and the expansion of market demand, FPC flexible circuit board custom manufacturing services will have broader development prospects and application areas.

FAQs

FPC flexible circuit board is a printed circuit board made of flexible base materials such as polyimide or polyester, which has excellent flexibility and bendability. It is widely used in consumer electronics, medical equipment, automotive electronics and other fields.

The advantages of FPC flexible circuit board custom manufacturing services include: small batch production, lightweight design, high-density wiring, high reliability, strong customizability, etc. These advantages help meet the different needs and personalized requirements of customers and improve product performance and reliability.

The process of FPC flexible circuit board custom manufacturing services includes requirements analysis, design, manufacturing, assembly, testing and verification, delivery and after-sales service. Each link requires strict quality control and process parameter control to ensure product performance and reliability.

In FPC flexible circuit board custom manufacturing services, the following problems may occur: bubbles, skip printing, oxidation, pinholes in graphics, dirt on the surface, etc. These problems may be related to manufacturing processes, material selection, environmental conditions and other factors.

Corresponding measures can be taken to solve problems that may arise in FPC flexible circuit board custom manufacturing services. For example: controlling the plating current and checking whether there are gaps in the scraper blade can solve the problem of skip printing; visually inspecting the copper foil on both sides of the printed board to see if there is oxidation can solve the oxidation problem; maintaining the cleanliness of the clean room can reduce surface dirt, etc.

Evaluating the quality of FPC flexible circuit board custom manufacturing services can be carried out in various ways, such as: checking the performance parameters of the product, testing the reliability of the product, customer feedback and market feedback, etc. These evaluation methods can help companies continuously improve service quality and product performance.