In China in 2024, recommended PCB manufacturers include Fumax, Pengding Holdings and Dongshan Precision, etc.

They have become the industry leader with their excellent technical strength, production capacity and market influence. A leader in the industry, providing customers with high-quality PCB products and services.

The following Chinese PCB manufacturers that may perform well in 2024 are recommended and introduced in detail:

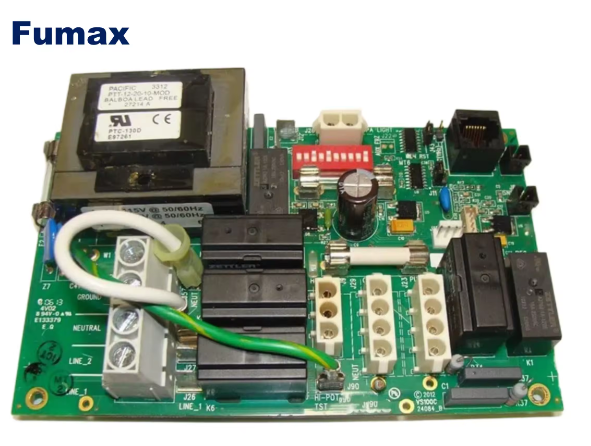

Fumax

Fumax is a PCB manufacturer in China. Fumax PCB (printed circuit board) manufacturer is an enterprise specializing in the design and production of printed circuit boards. These circuit boards are an integral part of electronic equipment and are used to connect and support various electronic components.

PCB manufacturers usually have full-process production capabilities from design, manufacturing to testing, as well as professional technical teams and advanced production equipment.

Pengding Holdings

Pengding Holdings is one of the world’s leading PCB manufacturers, known for its strong technical strength, production scale and market share. The company focuses on the R&D and production of high-end PCB products, which are widely used in communications, automobiles, consumer electronics and other fields. Pengding Holdings has advanced production equipment and manufacturing processes, and is committed to providing customers with high-quality, high-reliability products. At the same time, the company also focuses on R&D innovation and continuously promotes technological progress and industry development.

Dongshan Precision

Dongshan Precision is a well-known company in China’s PCB industry with strong R&D capabilities and production capabilities. The company’s products cover many fields such as communications, automotive electronics, consumer electronics, etc., and have won a good reputation in the market for their excellent quality and reliability. Dongshan Precision focuses on technological innovation and quality management, and continuously improves product performance and competitiveness. At the same time, the company also actively expands the international market and enhances brand influence.

Jianding Technology

Jianding Technology is an influential manufacturer in the PCB industry, focusing on the production and sales of high-end PCB products. The company has advanced production equipment and manufacturing technology and is committed to providing customers with high-quality and efficient PCB solutions. Jianding Technology focuses on R&D innovation and technology accumulation, and continuously launches competitive new products to meet the changing needs of the market.

Shennan Circuit

Shennan Circuit is one of the leading companies in China’s PCB industry, focusing on the R&D and production of high-precision and high-reliability PCB products. The company’s products are widely used in communications, automotive electronics, medical electronics and other fields, and have won the trust of customers with excellent quality and service. Shennan Circuit focuses on technological innovation and R&D investment, and continuously promotes the advancement and application expansion of PCB technology. At the same time, the company also actively participates in international cooperation and competition to enhance its overall strength and market competitiveness.

The PCB manufacturers recommended above have high visibility and influence in the Chinese market, and have strong technical strength and production capabilities.

However, due to the constant changes in market conditions and the uncertainty of enterprise development, it is recommended to fully understand their latest developments and development trends when choosing a partner. At the same time, other PCB manufacturers with potential and competitive advantages can also be considered to meet your specific needs and expectations.