PCB board (Printed Circuit Board) is an indispensable part of electronic equipment. Its quality and performance directly affect the function and reliability of the entire electronic equipment.

Therefore, during PCB board processing, processes and materials need to be strictly controlled to ensure optimal quality and performance. This article will introduce PCB board processing requirements and methods of selecting high-quality materials.

PCB board processing requirements

- Accuracy requirements: The accuracy requirements of PCB boards are very high, because even small errors may cause failure of the entire electronic device. Therefore, during the processing process, it is necessary to strictly control the accuracy of drilling, line printing, cutting and other links.

- Stability requirements: PCB boards need to maintain stable working conditions in various environments, so their materials and processes must have excellent stability and reliability.

- Durability requirements: PCB boards need to withstand long-term use, so their materials and processes must have excellent durability.

- Environmental protection requirements: With the improvement of environmental awareness, more and more companies are beginning to pay attention to environmental protection issues. Therefore, during the PCB board processing process, it is necessary to choose environmentally friendly materials and processes to reduce the impact on the environment.

How to select high-quality materials

- Choose reliable suppliers: Choosing reliable suppliers can ensure the quality and stable supply of materials. When selecting a supplier, factors such as its reputation, quality assurance system, and production capabilities need to be considered.

- Understand material properties: Different materials have different properties, so when selecting materials, you need to understand their electrical properties, mechanical properties, chemical properties, etc.

- Choose the appropriate base material: The base material of the PCB board is one of the keys, because it directly affects the electrical performance and mechanical strength of the board. When selecting a substrate, factors such as its thickness, material, and surface treatment need to be considered.

- Choose the right glue: During PCB board processing, glue is an important material used to fix electronic components and protect circuits. When selecting glue, you need to consider factors such as its bonding strength, temperature resistance, and curing speed.

- Choose the right ink: During PCB board processing, ink is an important material used to protect circuits and mark electronic components. When selecting ink, factors such as its adhesion, abrasion resistance, and temperature resistance need to be considered.

Summary

The quality and performance of PCB boards directly affect the functionality and reliability of the entire electronic device. Therefore, during PCB board processing, processes and materials need to be strictly controlled to ensure optimal quality and performance. This article introduces PCB board processing requirements and methods of selecting high-quality materials, including accuracy requirements, stability requirements, durability requirements and environmental protection requirements, and puts forward suggestions for selecting high-quality materials. By understanding these requirements and recommendations, PCB board materials can be better selected and applied, improving the quality and reliability of electronic equipment.

Among the PCB board processing requirements, which link has the highest accuracy requirements?

In PCB board processing, drilling and circuit printing are the two links that require the highest accuracy. The accuracy of drilling directly affects the position, diameter and depth of the holes, while the accuracy of line printing directly affects the shape, width and spacing of the lines. These accuracy requirements have an important impact on the electrical performance and mechanical strength of the PCB board. Therefore, during the PCB board processing process, the accuracy of drilling and line printing needs to be strictly controlled to ensure the best quality and performance of the entire PCB board.

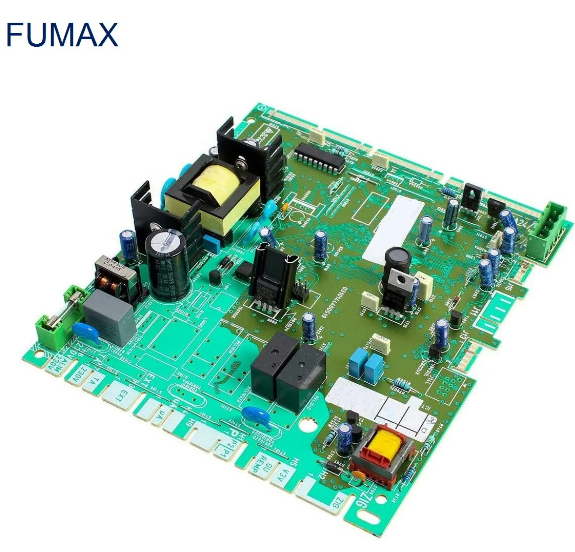

Fumax PCB processing factory

Fumax PCB processing factory is an enterprise specializing in PCB board processing and manufacturing. These factories have advanced production equipment and manufacturing technology and are able to provide various types of PCB boards according to customer needs.

When choosing a PCB board processing factory, you need to consider its production capacity, quality assurance system, price and other factors to ensure that your project can receive high-quality and efficient PCB board processing services.