PCB control board embedded system assembly and manufacturing is a complex and delicate process that requires multiple steps and expertise.

First, designers design the circuit board based on system requirements and select appropriate electronic components and wiring. Then, professional software is used to generate the firmware code of the embedded system and compile it into an executable binary file. Then, this file is burned into the chip or microcontroller to complete the integration of hardware and software. Finally, system testing and debugging are performed to ensure functional integrity and stability. In this process, precise control of each step and strict quality management are crucial.

- introduction

- Material preparation

- hardware design

- Hardware assembly

- Solder the microprocessor, memory and other components to the PCB.

- Connect the input and output interfaces and power module.

- Carry out power supply test to ensure that the power supply is stable and reliable.

- Carry out functional testing to check whether each module is working properly.

- Repair or replace unqualified parts to ensure overall performance and quality.

- software programming

- System testing and optimization

- Production and quality control

- Summary and Outlook

- Embedded PCB board manufacturer cost

- Embedded PCB board manufacturer

introduction

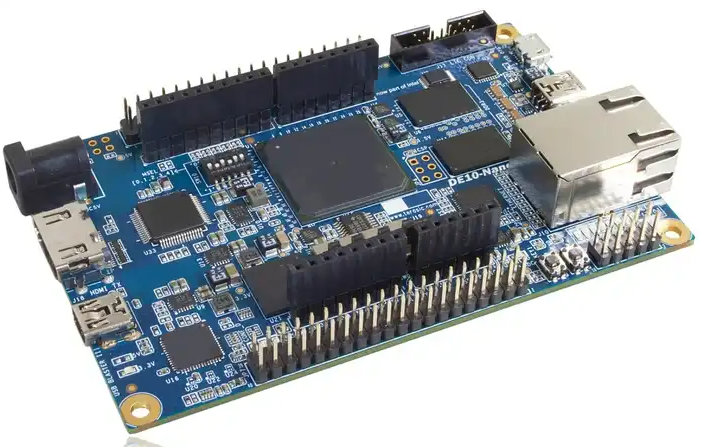

With the rapid development of science and technology, embedded systems have been widely used in various fields. PCB control board embedded system, as one of them, plays an important role in industrial automation, smart home, medical equipment and other fields with its high efficiency, flexibility, reliability and other characteristics.

This article will introduce in detail the assembly and manufacturing process of PCB control board embedded systems.

Material preparation

Before starting assembly and fabrication, you need to prepare the following materials:

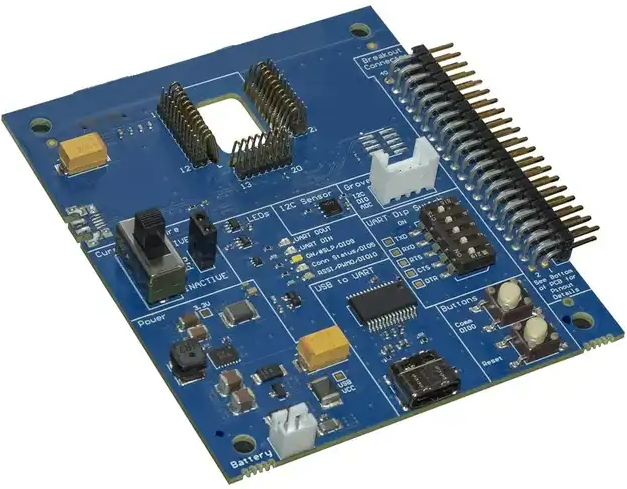

Embedded microprocessor (such as ARM, MIPS, etc.)

Circuit board (PCB)

Memory (such as RAM, Flash, etc.)

Input and output interfaces (such as GPIO, UART, I2C, etc.)

Power module

Other components (such as resistors, capacitors, diodes, etc.)

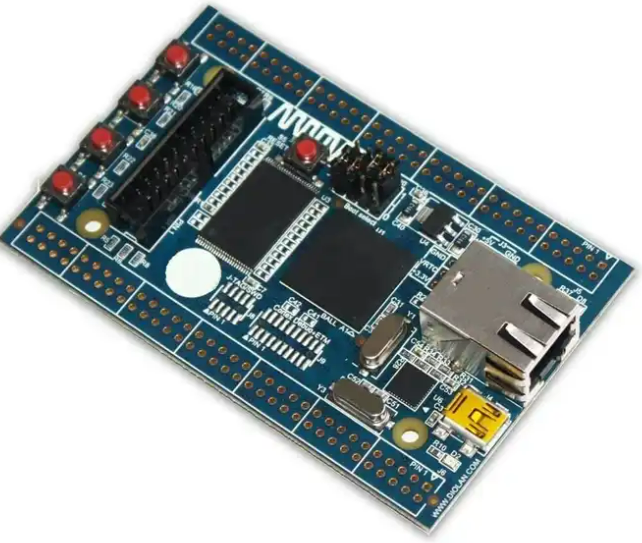

hardware design

Hardware design is one of the key links in the assembly and manufacturing of PCB control board embedded systems. It mainly includes the following steps:

Determine system functional requirements and hardware architecture.

Design circuit schematics and PCB diagrams.

Select appropriate components and determine their specifications and quantities.

Carry out PCB layout and wiring design.

Make samples and conduct functional and performance tests.

Hardware assembly

After all materials are prepared and hardware design is completed, hardware assembly can begin. Specific steps are as follows:

Solder the microprocessor, memory and other components to the PCB.

Connect the input and output interfaces and power module.

Carry out power supply test to ensure that the power supply is stable and reliable.

Carry out functional testing to check whether each module is working properly.

Repair or replace unqualified parts to ensure overall performance and quality.

software programming

Software programming of PCB control board embedded systems is an important part of realizing its functions. According to the hardware architecture and functional requirements, corresponding program code needs to be written. Generally speaking, software programming languages for embedded systems include C, C++, assembly language, etc. During the programming process, certain programming specifications and standards need to be followed to ensure the readability, maintainability and scalability of the code. At the same time, unit testing and integration testing are also needed to ensure the coordination and overall performance of software and hardware.

System testing and optimization

After completing the hardware assembly and software programming, the entire system needs to be rigorously tested and optimized to ensure that its performance and quality meet the requirements. The specific test steps are as follows:

- Carry out functional testing to check whether each functional module is working properly.

- Conduct performance testing, including testing of processing speed, response time, stability and other indicators.

- Conduct reliability tests, including long-term running tests, environmental adaptability tests, etc., to ensure that the system is stable and reliable in actual use.

- Conduct security testing to check whether the system’s encryption algorithm, firewall and other security mechanisms are effective.

- Optimize based on test results, including hardware and software optimization, to improve system performance and quality.

Production and quality control

After completing system testing and optimization, you can enter the production phase. Develop reasonable production plans and quality control standards based on customer needs and market positioning. During the production process, the quality of raw materials and production processes must be strictly controlled to ensure the quality and stability of each process.

At the same time, strict quality inspection and factory testing are required for finished products to ensure that the products meet customer requirements and market standards.

Summary and Outlook

The assembly and manufacturing of PCB control board embedded systems is a highly technical and complex process. Strict quality control and technical management are required at all stages to ensure the performance and quality of the final product. In the future, with the continuous advancement of technology and changing market demands, PCB control board embedded systems will face more opportunities and challenges. Therefore, we need to continuously strengthen our technological innovation and market development capabilities to adapt to a more fierce market competition environment.

Embedded PCB board manufacturer cost

The costs of embedded PCB board manufacturers mainly include raw material costs, labor costs, equipment costs, R&D costs, etc. Among them, raw material costs include the purchase of electronic components, PCB boards, auxiliary materials, etc.; labor costs include employee wages, training, management, etc.; equipment costs include the purchase of manufacturing equipment and tooling fixtures, etc.; R&D costs include the development of new products and new technologies. Required Fees.

These costs vary depending on the manufacturer’s size, technology level, production efficiency and other factors. Some manufacturers may reduce costs and improve market competitiveness by improving production efficiency, reducing scrap rates, optimizing supply chains, etc.

Embedded PCB board manufacturer

Fumax is a manufacturer specializing in embedded PCB board design, manufacturing, welding and assembly services.

We have rich industry experience and a professional technical team, and are committed to providing customers with high-quality, high-efficiency, and high-reliability embedded PCB board manufacturing services. Our services include PCB design, manufacturing, welding and assembly, as well as customized services, testing and verification, project management and technical support, etc.

We pay attention to details and quality, strictly control the production process and quality standards, and ensure the accuracy and stability of every link. Our goal is to provide customers with the best quality services and help customers improve the quality and competitiveness of their products.

The service items of embedded PCB board manufacturers mainly include the following aspects:

- PCB design: Provide professional PCB design services, including circuit board layout, wiring and component selection.

- PCB manufacturing: According to customer needs, manufacture PCB boards that meet specifications, including single-sided boards, double-sided boards, and multi-layer boards.

- Welding and assembly: Provide welding and assembly services, including component welding, patching, plug-ins, etc., to ensure the functional integrity and stability of the PCB board.

- Customized services: Provide customized PCB board services according to customer needs, including special sizes, materials, number of layers, etc.

- Testing and verification: Provide professional PCB board testing and verification services to ensure that the quality and performance of PCB boards meet customer requirements.

- Project management: Provide comprehensive project management services, including project progress management, quality management, risk management, etc., to ensure the smooth implementation of the project.

- Technical support: Provide technical consultation and support services, including the use of PCB design software, component selection, circuit schematic design, etc.

- Supply chain management: Provide supply chain management services, including raw material procurement, inventory management, logistics and distribution, etc., to ensure the smooth progress of production.

These service projects aim to provide customers with one-stop embedded PCB board manufacturing services to help customers shorten the research and development cycle, reduce production costs, and improve product quality and competitiveness.