Motor PCB design layout requirements

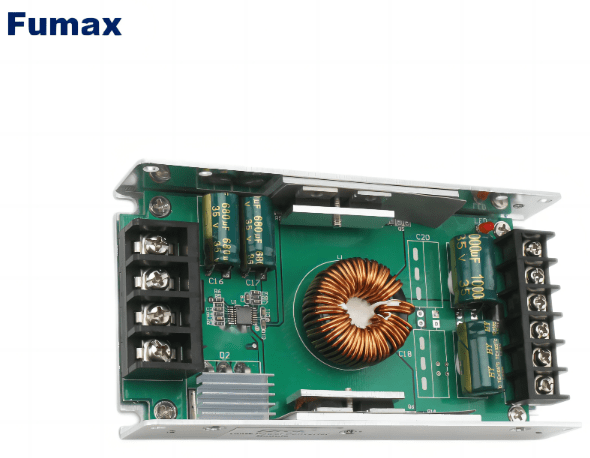

Motor PCB assembly OEM/ODM service companies provide customers with motor control board and motor controller PCB design and assembly services. Users can provide relevant BOM files and PCB files.

The requirements for motor PCB design layout include the following points:

- When the top components are too dense, some devices with limited height and low heat generation can be placed, and the chip IC is placed on the lower layer.

- Under the premise of ensuring electrical performance, components should be placed on the grid and arranged parallel or vertically to each other to maintain neatness and appearance. Under normal circumstances, components are not allowed to overlap, and components are arranged compactly and evenly distributed.

- The minimum distance between adjacent components should be less than 1MM.

- The edge of the board is not less than 2MM. The best shape for the board is a rectangle with an aspect ratio of 3:2 or 4:3.

- Arrange the position of each functional circuit unit according to the circuit flow, so that the layout facilitates signal circulation and keeps the signals as consistent as possible.

- Centering on the core components of each functional unit and surrounding it, the components are evenly and compactly arranged on the PCB board to minimize shortening of leads and connections between components.

- When making a package library, pay attention to the one-to-one correspondence between the schematic pins.

- The layout of the IC decoupling capacitor should be as close as possible to the IC power pin, and the loop formed between the power supply and ground should be as short as possible.

- When placing components, consider that devices using the same power supply should be placed together as much as possible to facilitate future power supply separation.

These requirements are all to optimize PCB design and improve its reliability and performance. Please note that these requirements are not hard and fast, and the specific design will be adjusted according to the actual situation and design goals.

What are the requirements for motor PCB design layout?

The specific requirements for motor PCB design layout include the following points:

- Ensure electrical performance: During layout design, electrical performance requirements, such as signal transmission speed, signal stability, etc., need to be taken into consideration.

- Component placement rules: When placing components, certain rules need to be followed, such as laying out according to functional units, maintaining appropriate distances and directions between components, and avoiding intersections and overlaps.

- Simple and beautiful: The layout design needs to be simple and beautiful, avoid being too complex and confusing, and facilitate subsequent maintenance and debugging.

- Consider thermal design: The motor will generate heat when working, so thermal design needs to be considered, and the location and heat dissipation method of components should be reasonably arranged to ensure the stability and reliability of the motor.

- Consider electromagnetic compatibility: The motor will be subject to electromagnetic interference when working, so it is necessary to consider electromagnetic compatibility and take measures to reduce interference, such as selecting appropriate components, adding filters, etc.

- Follow safety regulations: Motor PCB design needs to follow relevant safety regulations, such as avoiding contact with dangerous areas, avoiding overheating, etc., to ensure the safety and stability of the motor.

- Consider maintainability: The motor PCB design needs to take into account subsequent maintenance and debugging, such as easy component replacement and testing.

- Consider cost: The cost of motor PCB design also needs to be considered, such as selecting appropriate materials, reducing unnecessary components, etc., to reduce costs.

The motor PCB design layout needs to take into account electrical performance, aesthetics, safety, maintainability and other aspects to ensure the stability and reliability of the motor.