Overview

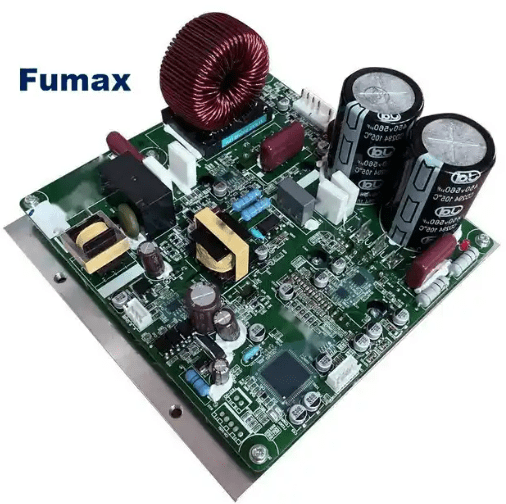

The motor drive controller PCB assembly process involves soldering electronic components to the printed circuit board to achieve motor drive and control. The process includes multiple steps, from component preparation, PCB cleaning, component placement, soldering, inspection to final testing. This article details these steps and their considerations.

Motor drive controller PCB assembly process

- Component preparation

Before starting assembly, you must first prepare the required electronic components, including integrated circuits, transistors, resistors, capacitors, relays, etc. These components are usually purchased from suppliers and selected and purchased according to the design requirements of the PCB board.

- PCB board cleaning

Cleaning the PCB board is an important step in the assembly process, as any impurities or oil stains can cause poor soldering or electrical failure. During the cleaning process, special PCB cleaners and lint-free cloths should be used to ensure that surface dirt and grease are removed. - Component placement

Place the components in the corresponding positions on the circuit board according to the PCB design requirements. Pay attention to the polarity orientation and nominal values of components to ensure they match the circuit design and actual hardware requirements. Components should be placed reasonably and neatly to facilitate soldering and inspection. - Component welding

Welding is a key step in motor drive controller PCB assembly, which directly affects the quality and performance of the product. During the welding process, the welding temperature curve and time requirements should be followed to ensure the quality of the solder joints. At the same time, undesirable phenomena such as welding bridging and cold welding should be avoided. After welding is completed, the solder joints should be checked for short circuits, weak soldering, etc. - Inspection and testing

After completing the soldering, strict inspection and testing should be carried out to ensure the normal function of the PCB board. The inspection content includes: whether the polarity and nominal value of the components are correct; whether there are short circuits or weak soldering in the solder joints; the electrical performance of the circuit board, etc. The test phase mainly involves power-on testing of the circuit board to check whether the motor drive controller is operating normally. If there is any abnormality, fault diagnosis and troubleshooting should be carried out. - Quality records and archiving

Throughout the PCB assembly process, detailed quality records should be kept, including component acceptance records, welding quality inspection records, test reports, etc. These records are critical to the quality control and subsequent maintenance of the product and should be properly archived and traceability maintained.

Notes

- Comply with safety regulations: During the PCB assembly process, be sure to comply with relevant safety regulations, such as wearing an anti-static bracelet and avoiding contact with high-temperature surfaces.

- Pay attention to details: Since there are many components on the PCB and they are densely arranged, you need to pay attention to every detail to ensure that each component is placed and soldered as required.

- Pay attention to quality: Motor drive controller PCB assembly has high quality requirements, so the quality of each step needs to be strictly controlled to avoid short circuits, false soldering and other undesirable phenomena.

- Continuous improvement: By analyzing and summarizing problems in the assembly process, we continuously optimize the process flow and improve production efficiency and product quality.

- Training and skills improvement: Regularly conduct skills training and assessment for employees to ensure that they have sufficient skill levels and are competent in motor drive controller PCB assembly work.

- Supply chain management: Select reliable suppliers and component suppliers to ensure that the quality and delivery time of components meet production requirements. At the same time, we pay attention to market dynamics, rationally adjust component inventory, and reduce costs.

- Environmental control: Keep the production workshop clean and hygienic to avoid dust, pollutants, etc. from affecting the PCB board. At the same time, pay attention to the impact of environmental factors such as temperature and humidity on PCB assembly.

Shenzhen Fumax Technology Co., Ltd. focuses on one-stop services such as motor drive controller PCB assembly, circuit board PCBA design and custom development, motor control board custom programming, SMT patching, DIP welding, motor PCBA testing and painting, etc.