The assembly process of the motor control board includes steps such as welding the motor, installing the Arduino, connecting the motor control board, connecting the power cord, and connecting the sensor. During the assembly process, it is necessary to select appropriate electronic components and protection devices, such as overload protection, short circuit protection, overvoltage protection, etc., to enhance the safety of the control board. At the same time, relevant regulations and operating requirements need to be followed, such as correct wiring methods, reasonable selection of power supply voltage, correct connection of sensors, etc. Operators need to undergo professional training and master correct operating skills and safety knowledge. To ensure security and stability, debugging and maintenance are also required.

Motor PCB assembly materials and process flow

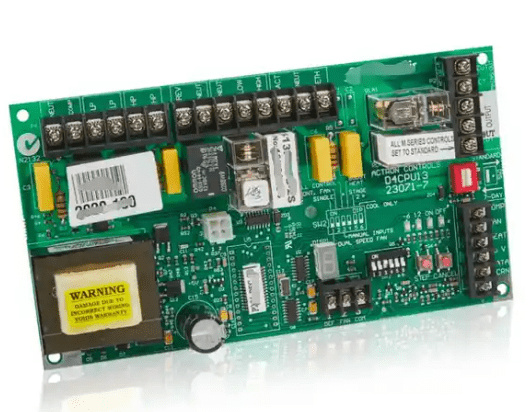

Motor control board assembly:

A motor control board assembly is a circuit board used to control the operation of a motor. The motor assembly control board usually contains various electronic components, such as resistors, capacitors, inductors, diodes, transistors, etc., as well as control circuits and protection circuits.

The design and manufacturing of the motor control board assembly need to take into account the motor type, power, speed, control requirements and other factors to ensure that the control board can meet the operating needs of the motor and ensure the stability and safety of the motor.

When designing and manufacturing motor assembly control boards, the following factors need to be considered:

- Power supply design: According to the power and voltage requirements of the motor, design an appropriate power supply circuit to ensure the stable operation of the motor.

- Control circuit design: According to the control requirements of the motor, design appropriate control circuits, such as speed control, direction control, protection circuits, etc.

- Protection circuit design: In order to protect the motor and control circuit from damage, it is necessary to design appropriate protection circuits, such as overload protection, short circuit protection, overvoltage protection, etc.

- Component selection and layout: Select appropriate electronic components and carry out reasonable layout to ensure the performance and reliability of the control board.

- Manufacturing process: Use appropriate manufacturing processes, such as PCB manufacturing, welding, assembly, etc., to ensure the quality and safety of the control board.

In short, the design and manufacture of motor assembly control boards need to take into account various factors, including motor type and control requirements, power supply design, control circuit design, protection circuit design, component selection and layout, manufacturing process, etc. Only by comprehensively considering these factors can a high-quality, high-performance, and high-reliability motor assembly control board be manufactured.

The steps to assemble the motor control board are as follows:

- Weld the motor: Weld the motor to the control board.

- Install Arduino: Place Arduino into the chassis and secure it.

- Connect the motor control board: Connect the motor control board to the Arduino by wiring or soldering.

- Connect the power cord: Connect the power cord to the motor control board, paying attention to the positive and negative poles of the power supply.

- Connect the sensor: If you need to use a sensor to control the motor, you need to connect the sensor to the motor control board.

- Debugging: After completing the assembly, debugging is required to ensure that the motor control board can work properly.

It should be noted that the assembly methods of different motor control boards may be different, and the specific steps and details need to be adjusted and operated according to the actual situation. At the same time, in order to ensure safety and stability, it is recommended to assemble and debug under the guidance of professionals.

Motor control panel assembly company

Here are some motor control board assembly companies:

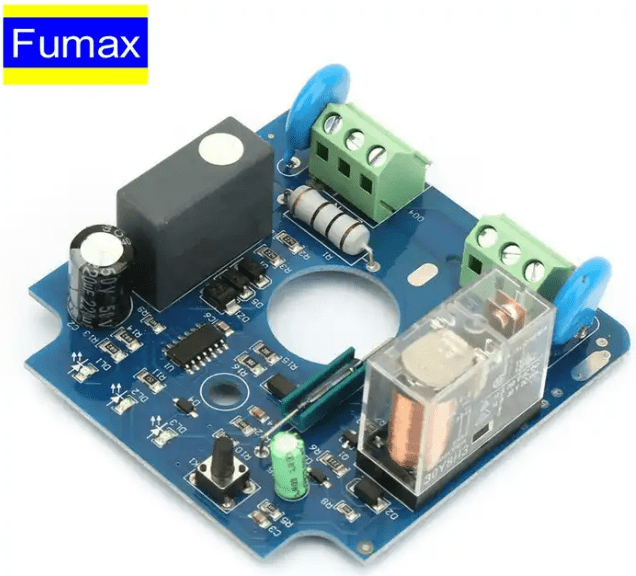

1.FUMAX: Shenzhen Fumax Technology Co., Ltd. is a world-renowned motor PCB manufacturing and PCB assembly service company, providing one-stop solutions for motor control board design, motor controller assembly and customization, motor control board design, and customized inverters. Control panel, electronic design and other technical services.

- Shenzhen INVT: Shenzhen INVT is a company focusing on industrial automation and energy and power fields. Its products cover inverters, motor control boards, industrial Internet, etc.

- Inovance Technology: Inovance Technology is a company specializing in industrial automation control products. Its products cover motor control boards, frequency converters, servo systems, etc.

- Zhongda Dentsu: Zhongda Dentsu is a company focusing on industrial automation and energy and power fields. Its products cover inverters, motor control boards, industrial Internet, etc.

- Lesai Intelligence: Lesai Intelligence is a company specializing in motion control products. Its products cover motor control boards, stepper motors, servo systems, etc.

The above companies are all well-known companies in the field of motor control board assembly and have certain market positions and technical strength. Of course, there are many other motor control board assembly companies, and you can choose according to your needs and actual situation.

How to ensure the safety of motor control board?

Ensuring the safety of your motor control board requires many aspects. Here are some suggestions:

- Design and manufacturing: The design and manufacturing of motor control boards need to comply with relevant standards and specifications to ensure the quality and reliability of the circuit board. At the same time, it is necessary to select appropriate electronic components and protection devices, such as overload protection, short circuit protection, overvoltage protection, etc., to enhance the safety of the control board.

- Installation and use: The installation and use of the motor control board need to follow relevant regulations and operating requirements, such as correct wiring method, reasonable selection of power supply voltage, correct connection of sensors, etc. At the same time, regular maintenance and inspection of the control panel is required to ensure its normal operation.

- Grounding and electrical isolation: The motor control board needs to be grounded and electrically isolated to prevent electrical fires and electric shock injuries. At the same time, grounding and electrical isolation also help improve the reliability and stability of equipment operation.

- Training and management: Personnel operating the motor control panel need to undergo professional training and master correct operating skills and safety knowledge. At the same time, relevant management systems and operating procedures need to be formulated to ensure that operators can comply with regulations and ensure the safety of equipment.

- Security protection: In some cases, the motor control board may be subject to external interference or attack, thus affecting its safety and stability. Therefore, corresponding safety protection measures need to be taken, such as installing filters, lightning protection facilities, etc., to enhance the safety and anti-interference ability of the control board.

In short, ensuring the safety of the motor control board requires starting from many aspects such as design, manufacturing, installation and use, grounding and electrical isolation, training and management, and safety protection to comprehensively improve the safety and reliability of the control board.

What are the components of the motor control board?

Motor control board assembly includes the following steps:

- Prepare materials: including motor control board, motor, power supply, sensors, etc.

- Install the motor: Install the motor on the motor control board.

- Connect the power supply: Connect the power supply to the motor control board, paying attention to the positive and negative poles of the power supply.

- Install the sensor: If you need to use a sensor to control the motor, you need to connect the sensor to the motor control board.

- Connect the lines: According to the control requirements of the motor, connect the various lines in the correct way.

- Debugging and testing: After completing the assembly, the motor control board needs to be debugged and tested to ensure that it can work properly and ensure safety performance.

It should be noted that the assembly methods of different motor control boards may be different, and the specific steps and details need to be adjusted and operated according to the actual situation. At the same time, in order to ensure safety and stability, it is recommended to assemble and debug under the guidance of professionals.

Key Steps What materials are needed for motor control board assembly?

Motor control board assembly requires the following materials:

- Circuit board: PCB board used to make control circuits.

- Motor: The motor that needs to be controlled.

- Power supply: The power supply that provides energy to the motor and control circuit.

- Sensor: A sensor used to sense the position, speed and other parameters of a motor or other equipment.

- Electronic components: including resistors, capacitors, inductors, diodes, transistors, etc., used to form control circuits.

- Connecting wires: used to connect the lines between motors, power supplies, sensors and circuit boards.

- Insulating material: Insulating layer used to protect motors and control circuits.

- Fasteners and supports: Used to hold the motor and control board in place.

- Radiator: used to dissipate heat for the motor and control circuit.

- Other auxiliary materials: such as solder, flux, cleaning agent, etc.

The exact quantities and specifications of these materials may vary based on specific motor control board assembly needs.

Motor control board assembly material specification sheet

Customizable Scope(PCBA Capacity)

| Supported Capabilities | |

| Types of Assembly | SMT (Surface-Mount Technology) |

| THD (Thru-Hole Device) | |

| SMT & THD mixed | |

| Double sided SMT and THD assembly |

| SMT capability | PCB material: FR-4, CEM-1, CEM-3, High TG, FR4 Halogen Free, FR-1, FR-2, Aluminum Boards; | |||

| Board type: Rigid FR-4, Rigid-Flex boards | ||||

| PCB layer: 1-32 layers; | ||||

| PCB thickness: 0.2mm-7.0mm; | ||||

| Copper thickness: Min:0.5oz; Max: 4.0oz; | ||||

| Assembly process | Lead-Free (RoHS, REACH) | |||

| Electrical testing | AOI (Automated Optical Inspection), | |||

| X-ray Inspection | ||||

| ICT (In-Circuit Test)/ Functional testing | ||||