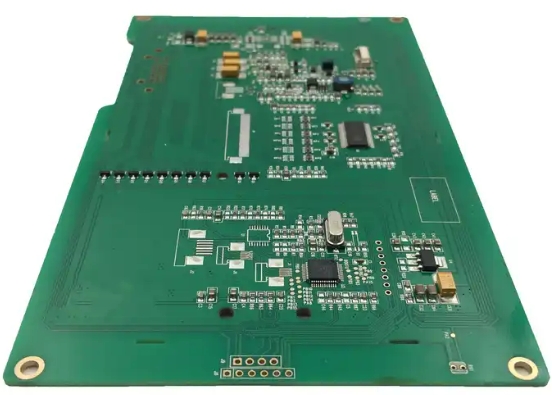

PCB copying means that on the premise that there are already physical electronic products and circuit boards, reverse research and development techniques are used to reversely analyze the circuit boards, and the PCB files, bill of materials (BOM) files, and schematic files of the original products are and other technologies.

The board copying steps of motor control board PCB assembly manufacturers may include the following aspects:

- Prepare drawings: Before starting to copy the board, you need to prepare a detailed drawing, including information about the components on the circuit board, wiring, and the structure of the PCB board.

- Disassemble components: First, you need to disassemble the components on the circuit board, and record the model, parameters, location and other information of each component.

- Scan the circuit board: Place the circuit board into the scanner, adjust the scanning parameters, and get a clear image of the circuit board.

- Process images: Use image processing software to process the scanned images, such as removing background noise, enhancing signals, etc.

- Identify components and traces: Use specialized PCB design software to identify each component and trace based on the processed image, and convert them into a circuit diagram form.

- Generate PCB files: Based on the recognition results, use PCB design software to generate corresponding PCB files, including top layer, bottom layer, power layer, etc.

- Verification and modification: After generating the PCB file, the file needs to be verified and modified to ensure the correctness and manufacturability of the file.

- Production: Finally, the PCB files are sent to the production line for production.

It should be noted that the board copying process requires professional skills and experience. Improper operation may cause damage to the circuit board or cause safety hazards. Therefore, it is recommended to understand the operating procedures and precautions in detail before copying the board, and choose appropriate tools and equipment for operation.

Manufacturer of motor control board PCB copying and assembly in Indonesia

In Indonesia, manufacturers that do motor control board PCB copying and assembly may include the following:

- Shenzhen Fumax Technology Co., Ltd. is a global PCBA design service provider, focusing on one-stop services such as motor control board PCB assembly, circuit board PCBA design, SMT patching, DIP welding, assembly testing, and painting.

- PT. Multi Karya Electronindo: This company specializes in the manufacturing and assembly of electronic products, including PCB assembly of motor control boards.

3.PT. Electro-Mech Industrial: This company is engaged in the manufacturing of electronic and electrical products, including PCB assembly of motor control boards.

4.PT. Penjualan Elektronik Indonesia: This company provides electronic product manufacturing services in Indonesia, including PCB assembly.

These companies may have professional PCB assembly equipment and skills and can provide high-quality motor control board PCB assembly services. You can contact these companies for more information and choose the partner that best suits your needs.