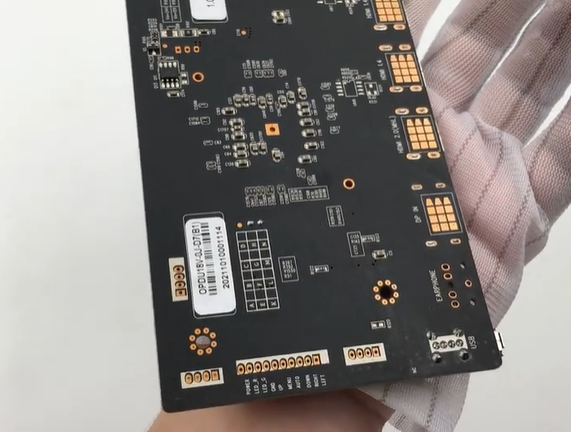

Material selection options for motor PCB board design

The material selection for motor PCB board design mainly depends on the type, specifications and performance requirements of the motor. The following are some common motor PCB board design materials:

- Substrate: Motor PCB boards usually use FR-4 (glass fiber reinforced plastic) as the substrate material. FR-4 has excellent mechanical properties and dimensional stability, making it the first choice for manufacturing ordinary PCBs. Other common substrate materials include CEM-3 (cellulose reinforced plastic) and aluminum substrates.

- Circuit: The circuit of the motor PCB board generally uses copper foil. Copper foil has excellent electrical conductivity and mechanical strength and is suitable for the manufacture of motor drive circuits.

- Welding materials: The welding materials for motor PCB boards generally use solder. The quality of solder directly affects the reliability and service life of PCB.

- Other materials: Other materials can also be added to the motor PCB board, such as shielding materials, isolation materials, packaging materials, etc., to ensure the correct operation and long-term stability of the circuit board.

In addition, some special high-performance motor PCB boards may require higher-grade materials. For example, using graphene as a substrate material can provide excellent electrical conductivity, thermal conductivity, and mechanical properties suitable for high-power and high-frequency electronic devices.

It should be noted that different materials have different characteristics. Therefore, when selecting the design materials for the motor PCB board, factors such as the type, specifications and performance requirements of the motor, as well as manufacturing costs and environmental factors need to be comprehensively considered.

Are there other common motor PCB board design materials?

In addition to the materials mentioned above, there are also some common motor PCB board design materials, such as:

- Insulating material: The insulating material on the motor PCB can prevent short circuits or leakage between different circuits. Common insulation materials include polyimide, polyester film, polytetrafluoroethylene, etc.

- Protective materials: The protective materials on the motor PCB can protect the circuit board from mechanical damage, chemical corrosion and environmental effects. Common protective materials include metal shells, silicone coatings, epoxy resins, etc.

- Adhesive material: The adhesive material on the motor PCB can bond different materials together to improve the stability and reliability of the circuit board. Common adhesive materials include thermosetting resins, hot melt adhesives, pressure-sensitive adhesives, etc.

- Filling material: The filling material on the motor PCB can fill the gaps on the circuit board and improve the mechanical strength and stability of the circuit board. Common filling materials include asbestos, fiberglass, carbon fiber, etc.

These materials are widely used in motor PCB board design and can meet the requirements of different types and specifications of motors. It should be noted that different materials have different characteristics. Therefore, when selecting the design materials for the motor PCB board, factors such as the type, specifications and performance requirements of the motor, as well as manufacturing costs and environmental factors need to be comprehensively considered.

Can you introduce some higher-level motor PCB board design materials?

sure. Here are some higher level motor PCB board design materials:

- High thermal conductivity materials: Some motors generate a large amount of heat when running, so high thermal conductivity materials need to be used to improve the heat dissipation performance of the PCB board. High thermal conductivity materials usually have high thermal conductivity and good thermal stability, such as aluminum substrates, copper substrates, carbon fibers, etc.

- High-frequency materials: Some motors require high-frequency signals to control, so high-frequency materials need to be used to improve the signal transmission performance of the PCB board. High-frequency materials usually have low loss and high-frequency characteristics, such as RT/Duroid, Rogers, F4B, etc.

- Anti-electromagnetic interference materials: Some motors need to work in a strong electromagnetic field environment, so anti-electromagnetic interference materials need to be used to improve the electromagnetic compatibility performance of the PCB board. Anti-electromagnetic interference materials usually have high electrical conductivity and high magnetic permeability, such as conductive graphene, carbon nanotubes, metal nanoparticles, etc.

- Wear-resistant materials: Some motors need to work in harsh environments, so wear-resistant materials need to be used to improve the durability and reliability of the PCB board. Wear-resistant materials usually have high hardness and good wear resistance, such as aluminum nitride, silicon nitride, silicon carbide, etc.

- Smart materials: Some motors require intelligent control and monitoring, so smart materials need to be used to improve the sensing and response capabilities of the PCB board. Smart materials usually have sensing and actuation functions, such as piezoelectric ceramics, shape memory alloys, electrostrictive materials, etc.

These high-grade materials can meet the specific needs of different types and sizes of motors, improving motor performance and reliability. However, these materials are usually more expensive, so factors such as motor performance requirements, manufacturing costs, and environmental factors need to be considered when selecting.

What are the advantages of using FR-4 substrate material in motor PCB board design?

Motor PCB board design using FR-4 substrate material has the following advantages:

- High temperature resistance: FR-4 substrate material has high heat resistance, can remain stable in high temperature environments, and is not easily deformed or damaged.

- High mechanical strength: FR-4 substrate material has high mechanical strength, can withstand large mechanical stress, and is not easy to break or be damaged.

- Good dimensional stability: FR-4 substrate material has good dimensional stability, which can ensure the accuracy and consistency of the PCB board.

- Easy to process: FR-4 substrate material is easy to perform drilling, cutting, milling and other processing operations, and can meet various processing requirements of motor PCB boards.

- Low cost: FR-4 substrate material is lower in cost than other advanced materials, which can reduce the manufacturing cost of motor PCB boards.

- Wide application: FR-4 substrate material is widely used in the design of motor PCB boards and has good reliability and stability.

In short, motor PCB board design using FR-4 substrate material can meet the performance requirements of most motors, and has good processing performance and cost advantages.

Top 5 motor pcb control design company reviews

- Shenzhen Fumai Technology Co., Ltd.

The motor PCB board design company selects materials. In addition to FR4 glass fiber PCB board materials, the motor PCB board design company selects the following materials:

High TG fiberglass: It is also a material made of glass fiber and epoxy resin. The epoxy resin is composed of special chemical components that can increase the glass transition temperature of the material. This material is more suitable for some application scenarios with harsh environments, high temperature and high pressure, such as automobiles and medical equipment.

Aluminum substrate: often used in application scenarios with high voltage, high heat, and strong electromagnetic fields. Its main advantages are good thermal conductivity, strong physical stability and strong friction resistance, but its manufacturing materials are relatively expensive.

Ceramic substrate: It is a PCB material based on ceramic materials such as aluminum oxide and silicon nitride. It has good high temperature resistance, corrosion resistance and mechanical strength, and is suitable for the manufacturing of high-frequency and high-power electronic products.

Polymer substrate: It is a PCB material based on polymer materials such as polyimide and polyamide. It has good high temperature resistance, chemical corrosion resistance and mechanical strength, and is suitable for the manufacture of high-performance electronic products. .

FR-4 glass fiber: It is the most commonly used material in PCB board production. It is made of finely divided glass fiber and epoxy resin interwoven with each other. It has good mechanical strength, heat resistance and chemical corrosion resistance, and also has good electrical properties and processing properties.

The above materials have their own advantages and characteristics, are suitable for different motor application scenarios, and can be selected according to actual needs.

Fumax is a high-tech company that provides comprehensive services in motor PCB board design, motor PCB assembly, PCBA solution design, PCB board manufacturing, and SMT patching. Motor PCB board design materials can be selected according to user requirements.

- Rogers. The PCB boards produced by Rogers Company have excellent high-frequency performance, thermal stability and chemical stability, and are widely used in communications, television, aerospace, automobiles, computers and other fields.

- Shengyi Technology. Shengyi Technology is one of the leading companies in PCB board materials, founded in 1985. The company mainly produces high-performance PCB board materials, including FR4, high TG FR4, aluminum substrates, etc. Its products are widely used in telecommunications, computers, consumer electronics, automotive electronics and LED lighting.

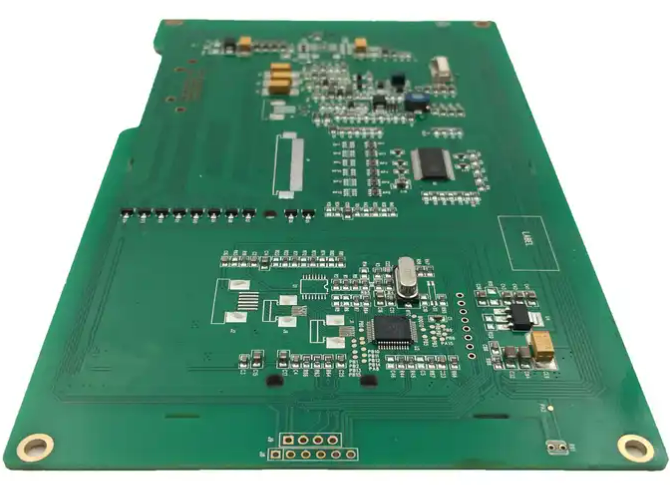

- Shennan Circuit is a manufacturer specializing in motor PCB design and is committed to providing customers with high-quality, high-performance PCB manufacturing services. The company has modern production equipment and professional technical personnel, focusing on the design and manufacturing of multi-layer printed circuit boards. Its products are widely used in electronics, communications, automobiles, medical equipment and other fields.

- DSBJ is a company focusing on PCB design, specializing in three major business sectors: electronic circuits, optoelectronic displays and precision manufacturing. The company has advanced equipment and manufacturing processes and can provide multi-layer, high-density, high-reliability PCB products. It has entered the top three global PCB companies in terms of revenue and ranks second in the world in terms of revenue in the field of flexible circuit boards. .

In what areas are motor PCB board manufacturers’ customized design and production used?

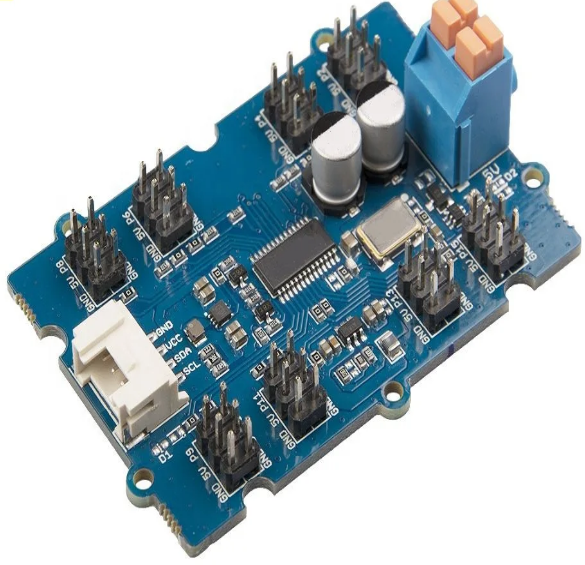

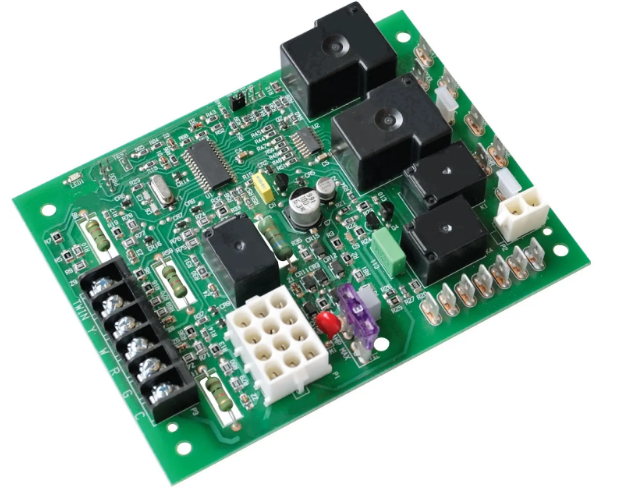

Motor PCB boards are mainly used in the following fields:

Medical equipment: Many medical equipment require separate basic PCBs, such as pH meters, heartbeat sensors, temperature measurement equipment, electrocardiographs, electroencephalographs, MRI machines, X-ray machines, CT scanners, blood pressure machines, blood sugar levels Measuring equipment, etc.

Industrial equipment: PCBs are also required in many industrial equipment, especially those industries with high-power mechanical equipment, such as arc welding, large servo motor drives, lead-acid battery chargers, military industry, clothing and cotton machines, etc.

Lighting field: LED lights and high-intensity LED lights are mounted on PCBs based on aluminum substrates because aluminum has the property of absorbing heat and dissipating it in the air.

Automotive and aerospace industries: Flexible PCBs are widely used because they are lightweight and can withstand high vibrations. Flexible PCBs can be adjusted even in tight spaces. These flexible PCBs serve as connectors, interfaces and can be assembled even in compact spaces.

The demand for PCBs in the above fields is huge, and the rapid development of these fields has driven the rapid development of motor PCB boards.

Can you list some special motor PCB board design materials for me?

Of course, here are some special motor PCB board design materials:

Metal-based copper-clad laminate: This material uses metal as the base material, such as aluminum, copper, etc., and is covered with a thin layer of copper foil. It has excellent mechanical properties and electrical conductivity and is often used to make high-frequency and high-power motor PCB boards. .

Ceramic-based copper-clad laminate: A copper-clad laminate based on ceramics has excellent high temperature resistance and electrical properties, and is suitable for PCB design of high-frequency and high-power motors.

High dielectric constant copper clad laminate: This material has a higher dielectric constant, which can provide better capacitor performance and is suitable for motor PCB boards that require high energy storage capacitor applications.

Copper-clad laminate for multi-layer boards with embedded passive components: This material embeds passive components in multi-layer boards, which can save space, reduce costs, and improve the performance and reliability of motors.

Copper-clad laminate for optical-electrical circuit substrates: This material has a photo-electric conversion function and can convert optical signals into electrical signals. It is suitable for motor PCB boards of photoelectric conversion devices.

Flexible copper-clad laminate: This material has good flexibility and bendability, and is suitable for motor PCB boards that require bending and deformation, such as automotive motors, medical equipment, etc.

The above materials have their own advantages and characteristics, are suitable for different motor application scenarios, and can be selected according to actual needs.

How do protective materials protect motor PCB boards from environmental influences?

Protective materials can protect the motor PCB board from environmental influences, mainly by coating a protective layer on the surface of the PCB board to isolate harmful substances in the environment, such as moisture, oxygen, corrosive gases, etc. Here are some of the main functions of protective materials:

- Isolation effect: The protective material can form a dense film on the surface of the motor PCB board to isolate the circuit board from the external environment and prevent moisture, oxygen and other harmful substances from penetrating into the circuit board, thus protecting the circuit board from environmental influences.

- Protection: The protective material can resist corrosive substances and mechanical damage in the environment, such as acidic gases, oxidizing atmospheres, etc., as well as prevent mechanical wear and collision, thereby protecting the integrity and reliability of the motor PCB board.

- Enhance circuit performance: Some protective materials can also enhance the electrical performance of the circuit, such as insulation resistance, dielectric loss, etc., as well as improve the anti-interference ability of the circuit to ensure the stability and reliability of the circuit.

- Common protective materials include conformal paint, epoxy resin, silicone, etc. These materials have good high temperature resistance, chemical corrosion resistance and mechanical strength, and can effectively protect the motor PCB board from environmental influences.

At the same time, these protective materials also have good processing properties and adhesion properties, can be easily coated and cured, and ensure the uniformity and stability of the protective layer.