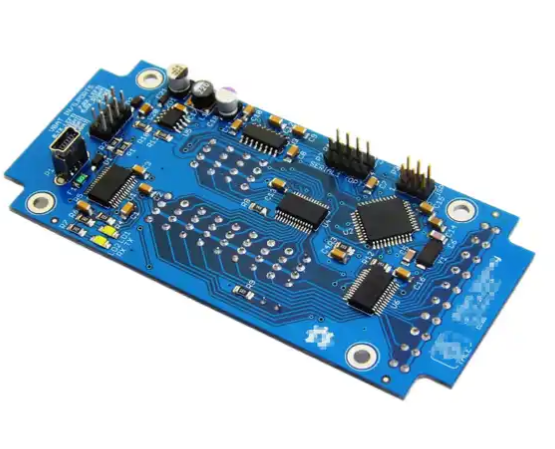

The layout design of PCB motor electronic controller is a key link in achieving controller performance, reliability, cost and maintainability.

Reasonable layout design can improve the anti-interference ability of the circuit, reduce energy consumption, improve operating efficiency, and at the same time optimize space utilization and reduce manufacturing costs.

In layout design, it is necessary to consider factors such as component selection, circuit protection, signal processing, heat dissipation design, electromagnetic compatibility, assembly and maintenance, and use simulation, optimization algorithms, modular design and other methods for optimization. Excellent layout design is one of the key factors to achieve high performance, high reliability and low cost of motor electronic controllers.

Fumax is a professional PCB manufacturing and PCB assembly manufacturer. If you have motor controller PCB design, manufacturing, and assembly needs, please contact us.

introduction

With the rapid development of power electronics technology, microcontrollers and sensor technologies, the layout design of motor electronic controllers is of great significance in improving motor performance, reducing energy consumption, and optimizing space utilization. Reasonable layout design can enhance the control accuracy of the motor and improve operating efficiency, while also reducing costs and improving product competitiveness. This article will provide an in-depth analysis of the layout design of motor electronic controllers.

Motor electronic controller layout design principles

- Functional principle: The layout design must first meet the functional requirements of the controller to ensure that the function realization of each component is not affected.

- Reliability principle: The selection and layout of each component should ensure the stability and reliability of the controller and avoid controller performance degradation or failure due to unreasonable layout.

- Efficiency principle: On the premise of satisfying functions and reliability, the efficiency of layout design should be improved as much as possible and manufacturing costs should be reduced.

- Maintenance principle: The layout design should consider the convenience of maintenance and repair, making it convenient for operators to perform daily maintenance and troubleshooting.

- Safety principles: Layout design should comply with relevant safety regulations to ensure the safety performance of the controller under normal operation and abnormal conditions.

Key points in layout design of motor electronic controller

Component layout

Reasonable layout of components based on circuit functions and current and voltage levels requires consideration of factors such as heat dissipation, electromagnetic compatibility, and signal transmission distance.

Power module layout

The layout of the power module should be as close as possible to the electrical load to reduce the length of the power cord and reduce losses. At the same time, the heat dissipation and isolation issues of the power supply should be considered.

circuit protection

Circuit protection should be fully considered in layout design, such as overload protection, short circuit protection, overvoltage protection, etc. Appropriate protection circuitry can enhance the safety and reliability of the controller.

signal processing

For input and output signals, the direction of the signal lines and the location of the interface must be reasonably arranged to ensure stable transmission and processing of signals.

Thermal design

According to the power consumption of the components and the ambient temperature, a reasonable heat dissipation design is carried out to ensure the stable operation of the controller.

electromagnetic compatibility

The influence of electromagnetic interference should be considered during layout design, and corresponding measures should be taken to improve the electromagnetic compatibility performance of the controller.

Assembly and repair

Consider the convenience of assembly and maintenance, and rationally arrange the location and disassembly of each component to improve production efficiency and maintenance quality.

Standardization and modularization

The adoption of standardized and modular design ideas facilitates the interchange and combination of controllers for different types of motors, while reducing production costs.

Motor electronic controller layout design optimization method

Simulation

Use professional software to simulate the layout design, predict the performance and reliability of the controller, and discover and solve problems in advance.

Optimization

Optimization algorithms such as genetic algorithm and particle swarm algorithm are used to optimize the layout design to find the optimal solution.

Modular design

The controller is divided into several modules, each module has specific functions to facilitate assembly and maintenance.

Automatic routing

Use automatic wiring software to route circuit boards to improve the efficiency and accuracy of wiring.

Parametric design

For commonly used components and parts, a parametric model is established to facilitate quick adjustment of layout design.

Reliability assessment

Conduct a reliability assessment of the layout design, including environmental adaptability, mechanical strength, electromagnetic compatibility, etc., to ensure the stability and reliability of the controller.

Cost analysis

Conduct detailed analysis of the cost of layout design, including material cost, manufacturing cost, maintenance cost, etc., to achieve cost control and optimization.

Iteration and optimization

In the preliminary design and detailed design stages, iterative optimization is continuously carried out to make the layout design more reasonable and perfect.

in conclusion

The layout design of the motor electronic controller is a key factor related to the performance, reliability, cost and maintainability of the controller. By following certain design principles and considering various design points, and adopting appropriate optimization methods, the quality and competitiveness of motor electronic controllers can be greatly improved.

In future development, with the continuous advancement of technology and the emergence of new demands, the layout design of motor electronic controllers will face more challenges and opportunities. Continuous research and innovation in layout design methods will help promote the development and application of motor electronic controllers.

PCB motor electronic controller layout design manufacturer

I’m glad you have read this. What are the excellent PCB motor electronic controller design manufacturers in China?

Fumax is a company specializing in PCB copying, PCB design, PCB modification, schematic design, drawing boards, Gerber files and other PCB related businesses. Since its establishment, the company has accumulated rich experience in PCB design, successfully developed tens of thousands of single and double-sided boards, and served many customers in the global market.

Professional PCB motor electronic controller design manufacturer with rich experience and excellent technical team, able to provide customers with high-quality services.