The PCB cloning industrial electrical motor control board process refers to the entire process of conducting a detailed analysis of the electronic components, circuit design, wiring methods, etc. on the circuit board, and then producing a replica board that is exactly the same as the original board based on the analysis results.

- Why do we need to do PCB cloning of industrial electrical appliances and motors?

- What are the difficulties and challenges of PCB cloning?

- How to perfectly design PCB clones?

- What are the requirements for PCB cloning?

- Can PCB assembly factories clone PCBs?

- What are the main steps in PCB cloning?

- Are PCB cloning and IC decryption the same?

- How to find a reliable PCB cloning manufacturer?

- China PCB manufacturing and PCB assembly manufacturers

Specific steps include: collecting information, determining PCB board dimensions and positioning holes, drawing schematic diagrams and PCB boards, component layout and wiring, board making and board copying. PCB cloning has the advantages of rapid replication and low cost, and has broad application prospects in the field of industrial electrical motor control.

Why do we need to do PCB cloning of industrial electrical appliances and motors?

Industrial electrical motors are a very important part of industrial control systems, and PCB circuit boards are one of its core parts. During the operation of industrial electrical motors, PCB circuit boards will be affected by various factors, such as high temperature, high pressure, vibration, etc., resulting in damage or failure. At this time, it becomes very necessary to copy the original PCB circuit board through PCB cloning technology.

First of all, PCB cloning technology can quickly copy a circuit board that is exactly the same as the original board, thus shortening the product development cycle. Secondly, the circuit board copied through PCB cloning technology has the same functions and performance as the original board, which can ensure the normal operation of industrial electrical appliances and motors and improve production efficiency. In addition, PCB cloning technology can also optimize and improve the original circuit board to meet the different needs of customers and increase the added value and market competitiveness of the product.

In short, PCB cloning technology for industrial electrical motors can ensure product quality and performance, shorten the research and development cycle, improve production efficiency, reduce costs, and increase the added value and market competitiveness of products. Therefore, in the field of industrial electrical appliances and motors, PCB cloning technology has very important application value and promotion significance.

What are the difficulties and challenges of PCB cloning?

The difficulties and challenges of PCB cloning mainly come from the following aspects:

- The complexity of circuit design increases: As the functions and performance of electronic products continue to improve, the complexity of circuit design is also increasing. This makes PCB cloning more difficult and requires a deeper understanding and mastery of circuit design.

- High manufacturing process requirements: PCB clones need to be produced in strict accordance with the manufacturing process of the original board, including board selection, stacking design, wiring method, etc. If the manufacturing process does not meet the requirements of the original board, it may cause the circuit board to have unstable performance or fail to work properly.

- Difficulty in component selection and layout: In the PCB cloning process, component selection and layout is a very important link. Improper component selection or unreasonable layout may affect the performance and stability of the circuit board.

- Signal integrity and EMC issues: In high-speed circuit design, signal integrity and EMC issues are very important. If these issues are not considered during the PCB cloning process, it may cause signal interference, electromagnetic radiation and other problems in actual use of the circuit board.

- Cost issue: The cost of PCB cloning is relatively high and requires a large investment of manpower and material resources. If costs are not properly controlled, the entire project’s profits may suffer.

To sum up, the difficulties and challenges of PCB cloning mainly come from the increased complexity of circuit design, high manufacturing process requirements, difficulty in component selection and layout, signal integrity and EMC issues, and cost issues. Therefore, when performing PCB cloning, these factors need to be fully considered and corresponding measures taken to solve the problem.

How to perfectly design PCB clones?

To design a PCB clone perfectly, you need to follow these steps:

Fully understand the original board

First, you need to fully understand the circuit design, wiring method, component selection and layout of the original board. You can gain in-depth understanding by analyzing the circuit schematic diagram, PCB diagram and other information of the original board, as well as observing the physical object of the original board.

Choose the right manufacturing process

According to the manufacturing process requirements of the original board, select the appropriate board material, stacking design, wiring method and other manufacturing processes. At the same time, signal integrity and EMC issues need to be considered to ensure that the cloned circuit board can meet performance requirements.

Component selection and layout

In terms of component selection and layout, the design ideas and actual application scenarios of the original board need to be taken into consideration. Try to choose the same component models and specifications as the original board, and place them in a reasonable layout. At the same time, signal integrity and EMC issues need to be taken into consideration to ensure the performance and stability of the circuit board.

Optimize routing and stack-up design

In terms of wiring and stack-up design, signal integrity and EMC issues need to be taken into consideration. Reasonably adjust the wiring and stacking design to ensure the stability and reliability of signal transmission. At the same time, it is necessary to pay attention to the impact of wiring and stacking design on circuit board performance to avoid problems such as signal interference and electromagnetic radiation.

Testing and Debugging

After completing the PCB clone design, testing and debugging are required. Through testing and debugging, possible problems can be discovered and improved. At the same time, you need to pay attention to safety issues during testing and debugging to avoid damage to the circuit board.

Optimize and improve

After testing and debugging are completed, the circuit board needs to be optimized and improved. Improve the performance and stability of the circuit board by optimizing the wiring and stacking design of the circuit board, and improving the selection and layout of components. At the same time, we need to pay attention to the cost issues in the optimization and improvement process to avoid over-design and waste.

To sum up, to perfectly design a PCB clone, you need to fully understand the original board information, choose an appropriate manufacturing process, reasonably select components and layout, optimize wiring and stack-up design, conduct testing and debugging, and optimize and improve the circuit board design. At the same time, you need to continue to learn and accumulate experience to improve your circuit design level and technical capabilities.

What are the requirements for PCB cloning?

PCB cloning requires the following conditions:

- Already have physical electronic products and physical circuit boards.

- Possess reverse R&D technical means, able to reversely analyze circuit boards and restore the structure, function and production process of circuit boards.

- Master the technical methods of PCB copying, including layering the circuit board, polishing the circuit board, measuring the circuit board, etc.

- Have professional tools and equipment, such as sandpaper, measuring instruments, etc., to ensure the accuracy and precision of copying.

- Understand the characteristics and manufacturing process of PCB boards, and be able to carry out corresponding optimization and improvement to improve the quality and efficiency of copying.

- Have corresponding awareness of intellectual property rights and laws and regulations, respect the intellectual property rights and laws and regulations of others, and shall not engage in illegal copying or infringement.

Can PCB assembly factories clone PCBs?

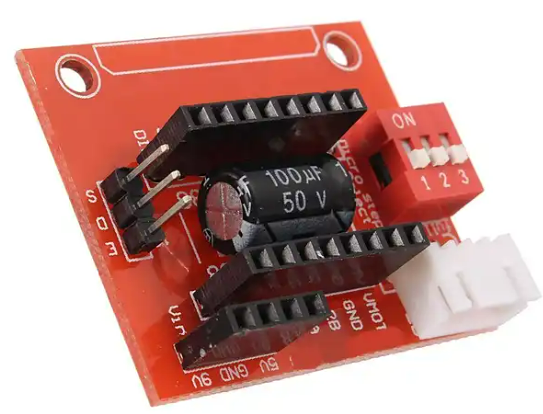

PCB assembly factories can clone PCBs. PCB cloning, which is equivalent to PCB copy board, is to use reverse research and development technology and advanced equipment to reverse analyze the circuit board on the premise that the physical electronic product and circuit board are already available, and convert the PCB files and materials of the original product Technical documents such as bill of materials (BOM) files, schematic files, and PCB silk screen production documents are restored 1:1, and then these technical documents and production documents are used for PCB board manufacturing, component welding, flying probe testing, and circuit board debugging. Complete a complete copy of the original circuit board template.

It is important to note that you must comply with intellectual property laws when copying PCB boards and ensure you have the legal rights to do so. Additionally, certain complex technologies or multi-layer boards may require specialized equipment and experience to replicate effectively.

What are the main steps in PCB cloning?

The main steps of PCB cloning include the following steps:

Collect electronic components and record them

Before cloning the PCB, you need to collect all electronic components and record their models, parameters and locations, including the directions of diodes, transistors and the direction of the IC notch. It’s a good idea to use a digital camera to take photos of component locations for later reference.

Disassemble components and clean PCB

Remove all components and remove the tin from the pads. Use alcohol to clean the PCB, then put it into the scanner, scan the screen printing surface in color, and print it out for later use.

Scan and print PCBs

Place the PCB horizontally and vertically in the scanner, otherwise the scanned image will not be usable. Adjust the contrast and lightness of the canvas so that the part with copper film and the part without copper film are in strong contrast. Then convert the picture to black and white and check whether the lines are clear. If not, repeat this step. If it is clear, save the image as a black and white BMP format file (such as top.bmp and bot.bmp). Then convert the two BMP format files into protel format files respectively, and transfer the two layers in protel. If the positions of the pads and vias on the two layers basically coincide, it means that the first few steps have been done well. If there is a deviation, repeat the third step.

Drawing components

Convert top.bmp to top.pcb, pay attention to convert it to the silk layer (yellow layer), and then draw lines on it. After painting, delete the silk layer. Similarly, convert bot.bmp to bot.pcb, also pay attention to convert it to the silk layer (yellow layer), and then draw lines on it. After painting, delete the silk layer.

Compare and check

Finally, merge the two PCB diagrams in protel and compare them for errors. If there are errors, you need to repeat the above steps. If it’s correct, you’re done!

Are PCB cloning and IC decryption the same?

PCB cloning and IC decryption are two different concepts.

PCB cloning is the reverse study of the physical electronic product and the physical circuit board. By reversely restoring the technical data of the circuit board, the circuit board is copied, cloned or digested and absorbed for technology fusion or secondary development. This is a reverse research process, mainly used to copy circuit boards and related technical data for product cloning or technology upgrades.

IC decryption, also known as microcontroller decryption, chip decryption, etc., is a decryption process for integrated circuits (ICs) or microcontrollers. Its main purpose is to unlock the program within the microcontroller in order to copy, analyze or obtain the intellectual property rights therein. Most microcontrollers have encryption lock bits or encryption bytes to protect on-chip programs from illegal acquisition or copying. IC decryption technology can help researchers obtain the internal programs and data of microcontrollers for related application development and research.

Although PCB cloning and IC decryption are two different concepts, they are similar in some aspects. For example, they all obtain technical and design information through reverse research on existing electronic equipment for replication, analysis, and secondary development. However, they target different objects, one is for the entire circuit board, and the other is for the integrated circuit or microcontroller.

How to find a reliable PCB cloning manufacturer?

To find a reliable PCB cloning manufacturer, you can take the following measures:

- Understand the qualifications and reputation of the manufacturer: When choosing a PCB cloning manufacturer, you must first understand the qualifications and reputation of the manufacturer. Check whether the manufacturer’s business license, tax registration certificate and other relevant documents are complete, and check whether there are any bad business records. At the same time, you can check whether the manufacturer has a professional R&D team and technical personnel, as well as past successful cases and customer reviews.

- Confirm the manufacturer’s professional fields: Different PCB cloning manufacturers may be good at different fields. For example, some manufacturers are good at cloning high-precision, multi-layer boards, and some are good at cloning high-speed boards and radio frequency boards. Therefore, when choosing a PCB cloning manufacturer, you must confirm whether the manufacturer has the professional knowledge and technical strength in the field you need.

- Examine the manufacturer’s production capacity and quality control: PCB cloning is a complex project that requires manufacturers to have advanced production equipment and strict quality control systems. When choosing a manufacturer, you can inspect the manufacturer’s production workshop, equipment and quality management system to understand its production capacity and quality control level.

- Refer to the reviews of other customers: If there are other customers who have cooperated with the PCB cloning manufacturer, you can refer to their reviews to evaluate the credibility and strength of the manufacturer. At the same time, you can understand the customer’s needs and project background so that you can better choose the manufacturer that suits you.

- Fully communicate with the manufacturer: When choosing a PCB cloning manufacturer, you must fully communicate with the manufacturer. Understand the manufacturer’s service process, delivery cycle, price policy and other relevant information, and inquire about the manufacturer’s specific plan and implementation plan. Through communication, you can better understand the manufacturer’s strength and service attitude, and whether it can meet your needs.

To sum up, to find a reliable PCB cloning manufacturer, you need to fully understand the manufacturer’s qualifications, professional fields, production capabilities, quality control, service attitude and other information, and carefully evaluate your needs and choose the appropriate manufacturer.

China PCB manufacturing and PCB assembly manufacturers

Shenzhen Fumax Technology Co., Ltd. is a PCB manufacturer that focuses on the manufacturing of PCB boards, including circuit board design, manufacturing and testing.

These manufacturers have advanced production equipment and technology and are able to produce various types of PCB boards, including high-precision, multi-layer boards, high-speed boards and radio frequency boards. Some well-known PCB manufacturers such as Fumax, AT&S, Jianding, Huizhou Zhongjing Electronics, etc.

Fumax PCB assembly manufacturer focuses on assembling electronic components onto PCB boards to achieve complete assembly of circuit boards. These manufacturers usually have professional assembly lines and testing equipment that can perform automated or manual assembly to meet the needs of different types of products. Recommended well-known PCB assembly manufacturers such as Fumax, Luxshare Precision, Goertek, Gongjin Technology, etc.

When choosing a PCB manufacturing and assembly manufacturer, you need to consider the manufacturer’s qualifications, professional fields, production capacity, quality control, service attitude and other information, and carefully evaluate your needs and choose the appropriate manufacturer.