The manufacturing cost of aluminum substrate LED PCB mainly includes material cost, equipment cost, labor cost and energy cost.

Among them, the material cost includes the cost of raw materials such as aluminum substrate, circuit layer, and insulation layer; the equipment cost includes the equipment, tools, molds and other expenses required to manufacture the aluminum substrate; the labor cost includes the wages, benefits and other expenses of technicians and workers; the energy cost Including the cost of electricity, water, gas and other energy required in the manufacturing process. In addition, manufacturing aluminum substrate LED PCB also requires certain management costs and maintenance costs.

What is aluminum substrate LED PCB?

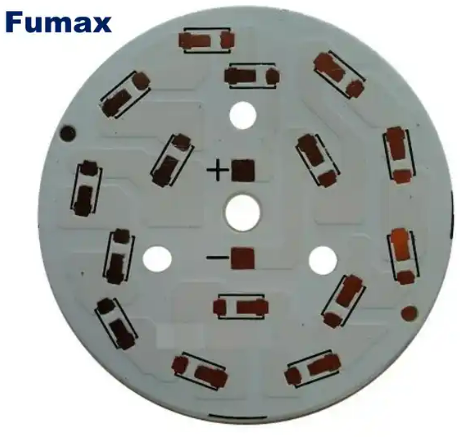

Aluminum substrate LED PCB is a special PCB board that uses an aluminum alloy plate as the base material and is covered with a circuit layer for installing and connecting LED lamp beads. This kind of PCB board has excellent heat dissipation performance and electrical performance, which can effectively solve the heat dissipation problem of LED lighting products and improve the life and light efficiency of LEDs.

What are the steps involved in the manufacturing process of aluminum substrate LED PCB?

The manufacturing process of aluminum substrate LED PCB includes the following steps:

- Prepare materials: Prepare aluminum substrate, circuit layer, insulation layer, metal base layer and other materials.

- Make the circuit layer: Cover the circuit layer on the aluminum substrate to connect the LED lamp beads.

- Make an insulating layer: Cover the insulating layer between the aluminum substrate and the circuit layer to prevent short circuits and electrical failures.

- Make a metal base layer: Cover the insulation layer with a metal base layer to improve the heat dissipation performance of the PCB board.

- Welding LED lamp beads: Weld the LED lamp beads to the circuit layer.

- Inspection and testing: Inspection and testing of the aluminum substrate LED PCB to ensure that its quality and performance meet the requirements.

What are the advantages of aluminum substrate LED PCB?

Aluminum substrate LED PCB has the following advantages:

- Excellent heat dissipation performance: Using aluminum alloy plate as the base material, it can quickly conduct heat and effectively solve the heat dissipation problem of LED lighting products.

- High electrical performance: It has high conductivity and low resistivity, which can improve the brightness and life of LED.

- Miniaturized design: The use of high-density design can reduce the size and weight of LED lighting products and facilitate installation and use.

- Strong weather resistance: It has good weather resistance and stability, and can work in harsh environmental conditions.

- Environmentally friendly materials: Made of environmentally friendly materials, harmless to the environment.

In short, the aluminum substrate LED PCB is a PCB board suitable for high-power LED lighting products. It has excellent heat dissipation and electrical properties and can improve the life and light efficiency of the LED. It is one of the important development directions of the LED lighting industry.

Aluminum substrate LED PCB manufacturing cost

The manufacturing cost of aluminum substrate LED PCB mainly includes the following parts:

- Material cost: including aluminum substrate, circuit layer, insulation layer, metal base layer and other material costs.

- Equipment costs: including the costs of equipment, tools, molds, etc. required to manufacture aluminum substrate LED PCBs.

- Labor costs: including labor costs such as technicians and workers required to manufacture aluminum substrate LED PCBs.

- Energy costs: including electricity, water, gas and other energy costs required to manufacture aluminum substrate LED PCBs.

- Other costs: including other costs required to manufacture aluminum substrate LED PCB, such as transportation, warehousing, management, etc.

The manufacturing cost of aluminum substrate LED PCB is affected by many factors, such as manufacturing process, production scale, material price, etc. Generally speaking, the equipment required to manufacture aluminum substrate LED PCBs is relatively expensive and requires high input costs. At the same time, labor costs and energy costs are also relatively high. However, with the continuous development of manufacturing technology and the gradual expansion of production scale, the manufacturing cost of aluminum substrate LED PCB will gradually decrease.

In order to reduce the manufacturing cost of aluminum substrate LED PCB, the following aspects can be considered:

- Optimize the manufacturing process: By optimizing the manufacturing process, production efficiency and product quality are improved, and the scrap rate and maintenance costs are reduced.

- Reduce material costs: Reduce material costs by negotiating with suppliers and finding alternative materials.

- Increase production scale: By expanding production scale, reducing fixed costs per unit product, increasing output and sales volume, thereby reducing manufacturing costs.

- Introduce automated production lines: Improve production efficiency and product quality, and reduce labor costs by introducing advanced technologies such as automated production lines and robots.

- Strengthen management: By strengthening production planning and scheduling management, inventory and warehousing costs are reduced, and capital utilization efficiency and management effectiveness are improved.

In short, reducing the manufacturing cost of aluminum substrate LED PCB requires starting from many aspects, by optimizing the manufacturing process, reducing material costs, increasing production scale, introducing automated production lines, strengthening management, etc., to continuously improve the competitiveness and market share of enterprises.

What are the aluminum substrate LED PCB manufacturers in China?

There are many aluminum substrate LED PCB manufacturers in China. fumax PCB manufacturer recommends the following ones for you:

Shenzhen Fumax Technology Co., Ltd.

It is a large-scale printed circuit board manufacturer specializing in the production of high-precision double-layer and multi-layer printed circuit boards. It has a full set of circuit board production and testing equipment. The company has obtained UL certification.

We have been engaged in R&D and manufacturing of aluminum substrates and copper substrates for many years, specializing in the production of LED aluminum substrates, copper substrates, automotive light panels, and high thermal conductivity aluminum substrates. We are a powerful copper substrate/aluminum substrate manufacturer in Shenzhen.

Taiyo Yuden (Suzhou) Co., Ltd.

Taiyo Yuden (Suzhou) Co., Ltd. is a wholly-owned subsidiary of Taiyo Yuden Co., Ltd. in China. It mainly produces aluminum substrates and LED aluminum-based circuit boards.

In 1950, Taiyo Yuden Co., Ltd. was born based on the successful commercialization of barium titanate ceramic capacitors. In the past fifty years, the company has grown and expanded with the development of the telecommunications product market. Today, we have become a leading company in the fields of capacitors, inductors, circuit modules and optical storage media such as CD-R and DVD-R. Our business scale is expanding globally. In addition to Japan, we have also established overseas production bases in South Korea, China, the Philippines, and Malaysia, and established international sales outlets in Europe, the United States, and Asia.

Shenzhen Huaqiang Electronics Co., Ltd.

It is a well-known enterprise in the field of aluminum substrates in China, specializing in the research, development, production and sales of various aluminum substrate products.