Remote control car toy PCB assembly customization services provide professional, efficient and reliable circuit board assembly and production, and are committed to meeting your needs for high-quality remote control car toys.

We use advanced production technology and strict quality control to ensure the perfect presentation of every detail and create a unique toy experience for you.

Remote control car toy PCB assembly customization is a process involving many aspects. The following is a detailed introduction to this process:

Remote control car toy PCB design stage

Before starting any PCB assembly, a detailed design phase first needs to be carried out. This phase includes the following steps:

- Clear requirements: Communication with customers is the key. Clearly understand the functions they want to achieve through this remote control car toy, as well as their requirements for performance, size, cost, etc.

- Toy remote control car PCB schematic design: According to the needs, design the electronic schematic diagram and clarify the connection relationship between each component.

- RC Car Toy PCB Layout: Based on the schematic design, carry out PCB board layout design to ensure that all components can be reasonably and efficiently arranged on the PCB board.

- Remote control car PCB wiring: After completing the component layout, carry out the wiring design of the PCB board to ensure that current can flow smoothly through the PCB board.

- Design review and optimization: Before the end of the design phase, conduct a design review to ensure the correctness and rationality of the design, and make necessary optimizations based on the review results.

Toy remote control car PCB material preparation stage

After completing the design, we enter the material preparation stage. The main task of this stage is to prepare all components and materials required for assembly. Includes the following steps:

- Component Procurement: Purchase the required electronic components based on the designed schematic diagram and PCB layout to ensure that the quality and specifications of the components meet the design requirements.

- Bill of Materials Preparation: Based on the design requirements, prepare a detailed bill of assembly materials, including PCB boards, electronic components, structural parts, screws, etc.

- Material Inspection: Quality inspection of purchased components and materials to ensure reliable quality and correct specifications.

Toy remote control car PCB board assembly stage

After preparing all the materials, enter the assembly stage. The main task of this stage is to assemble the various components onto the PCB board according to the design requirements. Includes the following steps:

- PCB board welding: Use welding technology to weld electronic components to the PCB board according to the designed layout. This step requires a high degree of skill and precision to ensure welding quality and reliability.

- Structural component assembly: Assemble the structural components to the PCB board according to the design requirements to form a complete remote control car toy frame.

- Functional Test: During and after assembly, perform functional testing to ensure that all functions of the remote control car toy can work properly.

- Quality Inspection: Conduct quality inspection on the completed assembled products to ensure that their quality and design requirements are consistent.

Remote control car PCB board packaging and delivery stage

After ensuring that the product quality is reliable, the packaging and shipping stage begins. The main task of this stage is to properly package the product and send it to the customer. Includes the following steps:

- Packaging Design: Design appropriate packaging methods based on customer needs and transportation requirements to ensure that the product is not damaged during transportation.

- Product Packaging: Pack the products that have passed quality inspection according to the design requirements.

- Shipping and Logistics Management: Send packaged products to customers to ensure fast and safe logistics. At the same time, we maintain communication with customers to ensure that they can pick up and process the products in a timely manner after receiving them.

- After-sales service preparation: Communicate with customers about after-sales service matters, including warranty period, maintenance procedures, etc. When necessary, have spare parts ready for customers’ emergencies.

- Continuous Improvement: Collect customer feedback and market information to understand product performance and potential room for improvement. Continuously improve product deficiencies to improve product quality and customer satisfaction. At the same time, we pay attention to industry dynamics and technological development trends, and promptly update product design and production processes.

Through the above detailed introduction, it can be seen that the customization of PCB assembly of remote control car toys is a process involving multiple links. Each link requires the support of professional knowledge and skills to ensure that the quality and performance of the final product meet customer requirements.

A factory that makes toy remote control car PCB customization in China

China has many factories specializing in the production of customized toy remote control car PCBs. They have advanced production technology and strict quality control, and are committed to providing efficient and high-quality customized services.

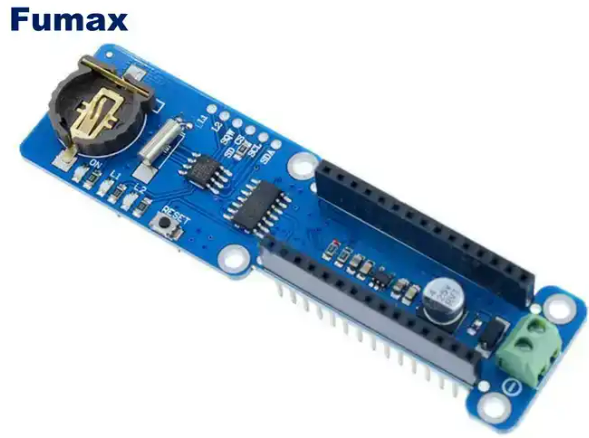

Fumax is a one-stop service manufacturer for PCB assembly, PCB design, PCB manufacturing and component procurement in China.

From design to production, we strive for excellence every step of the way to ensure that our customers’ unique needs are met. With excellent quality and considerate service, we have won the trust and praise of customers around the world.