Introduction

In today’s electronics manufacturing industry, PCBA (Printed Circuit Board Assembly) has become a vital component in many products. Whether it’s smartphones, computers, cars, or household appliances, precision circuit board assembly is indispensable. However, ensuring the quality and cost-effectiveness of PCBA requires collaboration with the right contract manufacturer. Inquiring about PCBA from manufacturers is not just a technical task, it’s an art that involves considering design requirements, material costs, production processes, and more to meet customer needs and ensure smooth production.

What flies/info are necessary?

To ensure accurate quotations, certain documents and information are essential. These include:

- Gerber: This file contains the layout information of the PCB, crucial for manufacturers to produce PCBs effectively.

- PCB Process/Manufacturing Requirements: Complex PCBs often come with separate documents detailing manufacturing process requirements like layer stacking, drilling, copper thickness, etc.

- BOM (Bill of Materials): A comprehensive list of all components required for PCBA, including specifications and quantities. Assembly Requirements: Instructions on component placement, soldering methods, cable and pin length requirements, and any special testing requirements.

- Quantity: Clear specifications on the required quantity, from samples to mass production.

- Other: Any additional special requirements, such as phased production or delivery deadlines. Improving Supplier Efficiency

“Hurry up! Please send me quote asap!”

To boost supplier efficiency, it’s important to provide as much information as possible. This allows suppliers to resolve issues independently when they arise, as many manufacturing engineering problems require cross-departmental or even cross-company collaboration. Here are some documents that can effectively enhance supplier efficiency:

Schematic Diagram: Helps suppliers understand the circuit design, aiding in identifying engineering issues during PCB production and assembly.

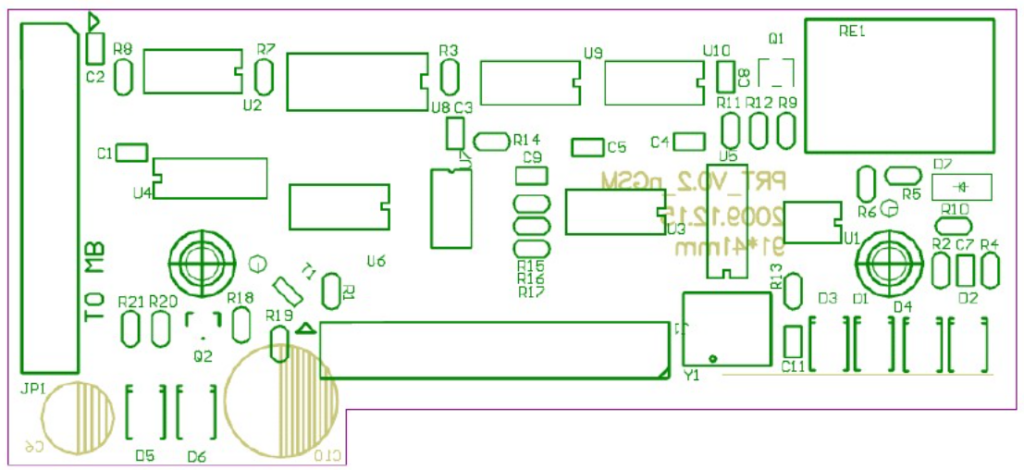

Silk Screen: Displays text, labels, and other information on the PCB, ensuring correct component placement.

Sample Images (Physical): Provides the most straightforward and clear quality check standards.

Clear Material Descriptions: Instead of just providing series names, BOM should include complete ordering part number for key components. Ordering sequences can be obtained from authorized suppliers and original manufacturers’ websites, or by directly providing datasheet for corresponding materials.

Assembly Instructions: Facilitates accurate assessment of production costs for suppliers.

Testing Instructions: Lists the equipment required for setting up tests and burning, particularly crucial for projects with special requirements like high-sensitivity sensors, custom transformers, or motors, and custom wiring harnesses. These documents help suppliers quickly resolve internal issues, avoiding back-and-forth email/phone communications.

How to select a reliable manufacturer?

When choosing a reliable contract manufacturer, it’s essential to consider both team capabilities and equipment quality, as their combination directly impacts product delivery quality. Equipment conditions are relatively easy to understand through the manufacturer’s website or on-site inspections, but team capabilities require deeper thought and investigation. Here are some considerations for team capabilities:

Firstly, take a look at the contract manufacturer’s procurement team size and years of experience. An experienced and adequately staffed procurement team can better coordinate with suppliers, ensuring timely material supply and avoiding production delays.

Secondly, whether the contract manufacturer has a professional engineering team, and whether their expertise matches your project requirements. Experienced engineering teams can provide professional technical support and advice for projects, promptly resolving issues during the production process to ensure product quality.

Thirdly, understand the types and quality of equipment at the contract manufacturer’s disposal, as well as the certificates they hold for products and companies. Advanced equipment typically enhances production efficiency and product quality, while holding relevant certificates indicates compliance with certain quality standards and production requirements.

Furthermore, the contract manufacturer’s production experience is also an essential consideration factor. Contract manufacturers with extensive experience are likely to possess the capability to solve various production issues and better cope with emergencies, ensuring production progress remains unaffected.

Lastly, consider the sales team at the contract manufacturer and their individual capabilities and communication skills. An efficient sales team can promptly respond to customer needs and quickly resolve issues, thereby establishing a good cooperative relationship. By comprehensively considering these aspects, we can more accurately select the right contract manufacturer, ensuring product quality and timely delivery.