MCU PCB prototype design to production manufacturing testing

MCU PCB prototyping is an important part of MCU application development. Its goal is to design and verify a PCB board that meets functional and performance requirements.

- MCU PCB prototype design to production manufacturing testing

- 1. What is MCU PCB prototyping?

- 2. Key steps in MCU PCB prototyping

- 3. What are the different MCU models?

- 4. How to improve the efficiency and quality of MCU PCB prototyping?

- 5. MCU PCB prototype design case

- 6. How to find a Chinese MCU PCB prototype design manufacturer?

- 7. What are the company names of PCB micro control unit design, development and processing manufacturers?

- 8. Top 5 PCB MCU prototyping factory manufacturers in China

- The following are common questions and answers about PCB MCU customization, design, and assembly

The MCU model, functional requirements, PCB size, number of layers and other special requirements need to be considered during the design process, while ensuring the reliability and stability of the design. The testing link is a key step to ensure that the prototype meets the design requirements, including functional testing, performance testing, reliability testing, etc. Through prototyping and testing, problems can be discovered and solved, ultimately leading to the transition from prototype to production. The entire process requires strict quality control and documentation for subsequent maintenance and use.

1. What is MCU PCB prototyping?

MCU PCB prototyping refers to the printed circuit board (PCB) design process based on MCU (microcontroller). The goal of this process is to create a PCB prototype to verify and test the functionality and performance of the MCU circuitry. MCU PCB prototyping is an important part of the hardware development process. It helps developers test and verify the circuit before actual manufacturing to ensure that it can meet the design requirements.

2. Key steps in MCU PCB prototyping

MCU PCB prototype design is the most critical step in the entire development process. It requires professional circuit design and PCB design technology, as well as strict testing and verification processes to ensure that the function and performance indicators of the chip can meet the needs.

The MCU PCB prototyping process usually includes the following steps:

- Determine requirements: Clarify the functional requirements and performance indicators of the MCU, as well as the size, number of layers and other special requirements of the PCB.

- Design schematic diagram: Use circuit design software to draw the MCU circuit schematic diagram to ensure that its functions are correct and meet the design requirements.

- Make PCB layout diagram: Convert the schematic diagram into PCB layout diagram and determine the location and connection method of components. This step requires consideration of PCB manufacturing constraints, such as board material, aperture, line width, etc.

- Component selection and layout: Based on the schematic diagram and functional requirements, select appropriate components and determine their layout and connection methods. The availability and reliability of components need to be taken into consideration, as well as signal integrity and electromagnetic compatibility.

- PCB manufacturing: Submit the PCB layout drawing to the manufacturing factory for PCB manufacturing. During the manufacturing process, attention needs to be paid to the quality and reliability of the PCB, as well as ensuring that the manufacturing meets the design requirements.

- Prototype assembly and testing: solder the components to the PCB and perform functional and performance testing. This step requires ensuring that the function and performance of the circuit meet the design requirements, and debugging and solving problems.

- Optimization and document writing: Based on the test results, optimize and improve the circuit, and write relevant design documents, such as schematic diagram, PCB layout diagram, component list, etc.

MCU PCB prototyping is a key link in the hardware development process. It can help developers verify the function and performance of the circuit, while discovering and solving potential problems to ensure the quality and reliability of the final product.

3. What are the different MCU models?

There are many different MCU models, including GD32, AT32, Nationz Technologies, Zhongkexin, GigaDevice, Huada Semiconductor, Artili, AMEC, etc.

Each model has its specific features and performance specifications and can be selected based on specific application needs.

When selecting an MCU, factors such as its processing power, memory size, available peripherals and interfaces, power consumption, and cost need to be considered. In addition, the reliability and stability of the MCU also need to be considered to ensure that it can meet the needs of the application.

4. How to improve the efficiency and quality of MCU PCB prototyping?

Here are some ways to improve the efficiency and quality of MCU PCB prototyping:

- Clarify the design requirements and goals: Before starting the design, it is necessary to clarify the functional requirements and performance indicators of the MCU, as well as the size, number of layers and other special requirements of the PCB. At the same time, clear design goals need to be set, such as reducing costs and improving reliability.

- Choose appropriate development tools and software: Choosing powerful circuit design software and PCB layout and routing tools can improve design efficiency and quality. At the same time, using professional EDA tools can reduce design errors and avoid potential problems.

- Reasonable planning of the design process: Designing according to a reasonable design process can reduce duplication of work and improve efficiency. For example, schematic design is carried out first, then PCB layout and wiring design is carried out, and finally prototype production and testing are carried out.

- Pay attention to component selection and layout: The selection and layout of components have a great impact on the efficiency and quality of PCB prototype design. Selecting appropriate components can improve the performance and reliability of the circuit, while a reasonable layout can reduce problems such as signal interference and reflection.

- Pay attention to the constraints of PCB manufacturing: PCB manufacturing constraints such as board material, aperture, line width, etc. have a great impact on the design. Consider these constraints during the design process to avoid manufacturing errors and delays.

- Strengthen electromagnetic compatibility design: Electromagnetic compatibility is one of the important considerations in MCU PCB prototype design. Through reasonable circuit design and layout, problems such as electromagnetic interference and signal interference can be reduced and the reliability and stability of the design can be improved.

- Pay attention to testing and verification: Testing and verification are key links to improve the efficiency and quality of MCU PCB prototype design. Through functional testing and performance testing, potential problems can be discovered and solved to ensure that the function and performance of the circuit meet the design requirements.

- Continuously optimize and improve the design: During the MCU PCB prototype design process, continuous optimization and improvements must be made to improve the performance and reliability of the circuit. For example, by optimizing the selection and layout of components and improving circuit design, the efficiency and quality of the design can be improved.

In short, improving the efficiency and quality of MCU PCB prototype design requires starting from many aspects, including clarifying design requirements and goals, selecting appropriate development tools and software, rationally planning the design process, paying attention to component selection and layout, and paying attention to the limitations of PCB manufacturing. conditions, strengthen electromagnetic compatibility design, pay attention to testing and verification, and continuously optimize and improve the design, etc. Through the implementation of these measures, the efficiency and quality of MCU PCB prototype design can be effectively improved.

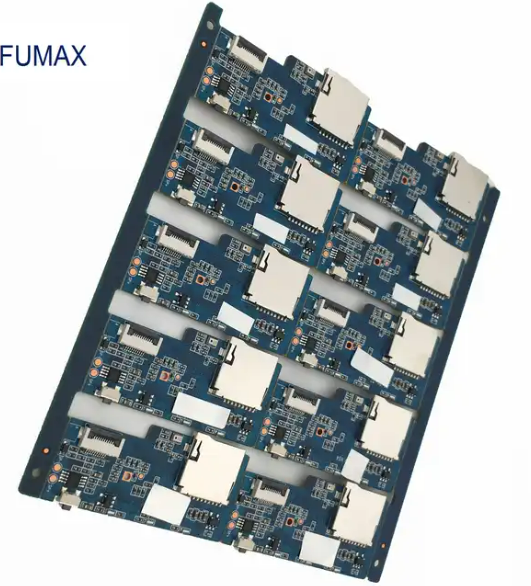

5. MCU PCB prototype design case

The following is an example of MCU PCB prototype design:

A company has developed a smart home control system based on MCU, in which the MCU needs to implement data collection and control functions with multiple sensors. In order to ensure that the function and performance indicators of the circuit can meet the needs, the company conducted MCU PCB prototype design.

During the MCU PCB prototyping process, the company first clarified the functional requirements and performance indicators of the MCU, as well as the size, number of layers and other special requirements of the PCB. Then, use circuit design software to draw the MCU circuit schematic and ensure that it functions correctly and meets the design requirements. Next, a PCB layout diagram was made to determine the location and connection methods of components, taking into account the constraints of PCB manufacturing, such as board material, aperture, line width, etc. In terms of component selection and layout, the company selected components that met functional requirements and reliability requirements, taking into account factors such as signal integrity and electromagnetic compatibility. Then, the PCB layout drawing is handed over to the manufacturing factory for PCB manufacturing and ensures that the manufacturing meets the design requirements.

During the prototype assembly and testing phase, the company soldered the components to the PCB and conducted functional and performance testing. During the testing process, the company discovered some signal interference and reflection problems and made corresponding optimizations and improvements. Finally, the company compiled relevant design documents, such as schematic diagrams, PCB layout diagrams, component lists, etc., for subsequent maintenance and use.

Through the MCU PCB prototyping process, the company successfully verified the circuit functions and performance indicators of the smart home control system and improved the quality and reliability of the product. At the same time, this case also demonstrates the importance and necessity of MCU PCB prototyping.

6. How to find a Chinese MCU PCB prototype design manufacturer?

You can find us by searching for Fumax MCU PCB prototyping manufacturer on Google. Of course, we have shared with you the top 5 PCB MCU prototyping factory manufacturers in China.

Fumax is a technical service company specializing in printed circuit board (PCB) production and prototype PCB assembly. We provide customers with PCB layout design, PCB sample manufacturing, PCB mass production, PCB expedited production, PCB placement (PCBA), etc. Series of customized services.

7. What are the company names of PCB micro control unit design, development and processing manufacturers?

In China, there are many well-known PCB MCU prototype design, development and processing manufacturers. Fumax will introduce some well-known PCB design, development and processing companies. These companies have rich experience and expertise in the field of PCB design and processing, and provide customers with high-quality PCB products and services.

8. Top 5 PCB MCU prototyping factory manufacturers in China

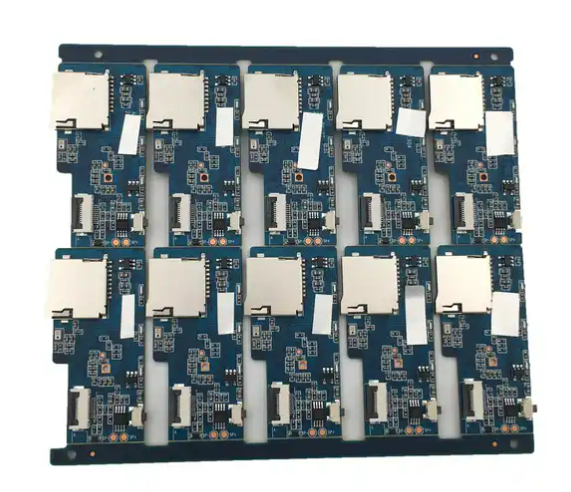

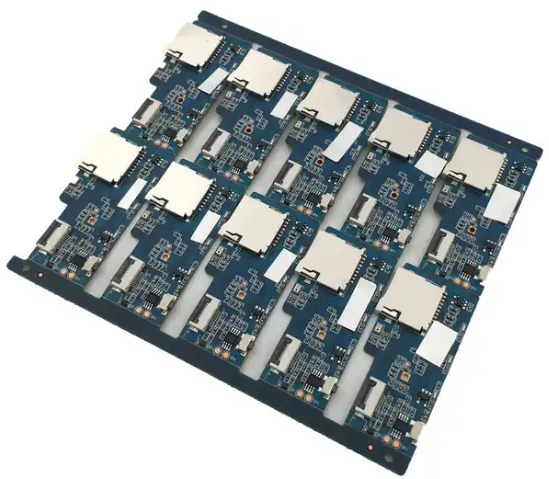

8.1 Shenzhen Fumax Technology Co., Ltd.

China’s global PCB assembly and prototype PCB manufacturing service factory. It has been engaged in one-stop services such as MCU PCB design, circuit board PCBA design and custom development, software programming, component procurement, SMT patching, DIP welding, assembly testing and painting for many years. .

The manufacturing service products provided involve industrial control, vehicle systems, MCU, remote communications, smart home, medical equipment and consumer electronics and other fields.

8.2. XYZ Electronics Co., Ltd.

XYZ Electronics Co., Ltd. is a well-known PCB design and processing manufacturer. They have many years of experience and expertise and a good reputation in the field of PCB design and processing. Their products are widely used in aerospace, medical equipment, industrial control and other fields.

8.3. DEF Electronic Technology Co., Ltd.

DEF Electronic Technology Co., Ltd. is a professional PCB design and processing manufacturer. They have first-class equipment and technical teams that can meet the various needs of customers. The quality of their products is stable and reliable, and they are widely praised by customers. Their customers mainly come from electronic communications, industrial automation, new energy and other fields.

8.4. MNO Electronics Co., Ltd.

MNO Electronics Co., Ltd. is a company specializing in PCB design and processing. They have advanced production equipment and technical teams to provide high-quality PCB products and solutions. Their products are widely used in consumer electronics, automotive electronics, industrial control and other fields.

8.5. HHcircuits Co., Ltd.

HHcircuits Xinfeng Huihe Circuit Co., Ltd. is a company specializing in PCB design and processing. They have advanced equipment and technical teams to provide high-quality PCB products and solutions. Their customers are all over the world, including consumer electronics, communication equipment, automotive electronics and other industries.

The above are some well-known PCB design, development and processing manufacturers in China introduced by fumax. These companies have rich experience and professional knowledge in the field of PCB design and processing, and can provide customers with high-quality PCB products and services.

If you need PCB design and processing services, consider contacting these companies to meet your needs. There are many other companies that offer similar services.

Fumax provides you with PCB MCU design customization services, including one-stop services from raw material procurement, design, manufacturing, assembly, testing, packaging, etc.

When choosing a partner, it is recommended that you conduct adequate market research and comparisons to ensure you choose the company that best suits your needs.

The following are common questions and answers about PCB MCU customization, design, and assembly

A: Generally speaking, in order not to affect the signal integrity of the analog part as much as possible, whether the regulated power supply chip is relatively clean and has a small ripple power supply, the power supply for the analog part has relatively high requirements. Whether the analog part and MCU have the same power supply, in high-circuit designs, it is recommended to separate the power supplies of the analog part and the digital part. The power supply to the digital part needs to be considered to minimize the impact on the analog circuit part.

A: The solution is to choose a router with a strong winding engine, because most of them have set constraints to control the winding method and the number of vias, and can manually adjust the difficulty of wiring, which can be effective Resolve the conflict between the two.

A: You can increase the distance between high-speed signals and analog signals, and pay attention to the noise interference of digital ground to analog ground.

A: First, the length of the two lines should be as long as possible, and second, the distance between the two lines should remain constant, that is, remain parallel. Parallel methods can be divided into two types. One is that two lines run on the same wiring layer, and the other is that two lines run on two adjacent layers above and below. Generally, the former is the most common way.

A: In high-speed digital circuits, in order to improve signal quality and reduce wiring difficulty, multi-layer boards are generally used and dedicated power layers and ground layers are allocated.

A: Generally speaking, it is recommended that the ground wire should form a closed sum.