A microcontroller is an integrated circuit that implements specific control functions, while a PCB is a substrate that provides electrical connections between electronic components. The two play different roles in electronic equipment.

Overview of the difference between microcontroller and PCB

In electronic engineering, microcontroller and PCB are two important concepts that each play a unique role and depend on each other to a great extent.

However, although they are both critical parts of electronic devices, they have significant differences in functionality and manufacturing.

Microcontroller and PCB definition and functions

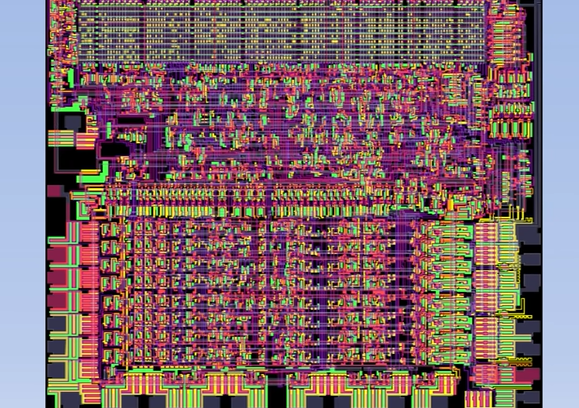

- Microcontroller (MCU): It is an integrated circuit that integrates a processor, memory, input/output interfaces and other functional modules on a silicon chip. MCU is mainly used to execute programs, control and manage various electronic systems. It can be viewed as a microcomputer capable of processing information, executing programs, and controlling external hardware.

- Printed circuit board (PCB): It is a substrate that provides electrical connections between electronic components. Conductive patterns are engraved on the PCB, and these patterns connect various components according to the design requirements to realize the function of the circuit. PCB is the skeleton of electronic equipment, supporting and fixing components and providing electrical connections.

Analysis of the differences between microcontroller and PCB

- Function and purpose: The main purpose of MCU is to execute programs and control functions, while the main purpose of PCB is to provide electrical connections between electronic components, support and fix components.

- Design complexity: MCU design involves both hardware and software aspects, and requires the implementation of specific control logic or algorithms. PCB design mainly focuses on electrical connections and mechanical structures to ensure the correct installation and connection of components.

- Application fields: MCU is widely used in various automation equipment, intelligent instruments, control systems and other fields to realize the intelligence and automation of equipment. PCB is widely used in various electronic devices, such as mobile phones, computers, TVs, etc., as the basis for realizing circuit functions.

- Manufacturing process: The manufacturing of MCU involves semiconductor processes, which require the production of extremely tiny circuits and devices on high-purity silicon wafers. The manufacturing of PCB involves metal conductor pattern production, insulation layer covering, surface treatment and other processes, and its manufacturing process is relatively simple.

- Updates and upgrades: Since the MCU integrates program memory and processor, its functions can be upgraded or changed through software updates. Once a PCB is manufactured, its electrical connections and physical structure are determined and cannot be upgraded or changed through simple methods.

- Troubleshooting and repair: When the MCU fails, it may be necessary to troubleshoot through a programmer or emulator. When a PCB fails, the problematic component or the entire circuit board may need to be replaced.

- Cost and price: The cost of MCU mainly comes from its internal processor, memory, interface circuit and other components, so the price is relatively high. The cost of PCB mainly comes from material and manufacturing costs, so the price is relatively low.

Relationship and cooperation between microcontroller and PCB

Although MCUs and PCBs have significant differences in functionality and manufacturing, they work well together in practical applications. MCU needs to connect various electronic components through PCB to realize its control function. PCB requires MCU to drive and control various electronic devices. In practical applications, selecting the appropriate MCU and PCB is crucial to achieve the performance and stability of electronic devices.

Microcontroller and PCB Conclusion

In general, microcontrollers and PCBs each play a unique role in electronic engineering and have significant differences.

MCU is mainly used to execute programs and control functions, while PCB is mainly used to provide electrical connections between electronic components.

In practical applications, selecting the appropriate MCU and PCB is crucial to achieve the performance and stability of electronic devices.

Understanding the differences between MCUs and PCBs can help you better understand the working principles and design requirements of electronic devices.