The product range of Flexible & Rigid Flex PCBs that Fumax can offer:

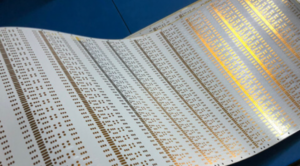

Flexible PCBs

• Features — Flexible printed circuit boards based on polyimide, from single-sided to multilayer flex. Light and thin, helping reducing the size and weight of electronic products. High wiring density、free bending, winding, and folding、high flexibility、excellent heat dissipation and solderability with SMD population and underfill.

• Competence — Material Type(PI/LCP/PTFE); Layer(1-10); Thickness of The Finished Product(0.1-0.8mm); Dimension of The Finished Product(9*22inch); Minimum Bending Radius(3-6 times board thickness); Line Width/Space(2.5/2.5mil); Dimension Accuracy(±0.05mm).

Semiflexible PCBs

• Features — Thin, double-sided FR4 materials. Maximum of five bending cycles with a 5mm bending radius. Cost effective flex-to-install solutions. Soldering without pre-baking. More stable construction, simplifying handling during assembly.

• Competence — Materials(FR4 (125µm Dielectric)); Layer(2 Layer PTH); Thickness of The Finished Product(0.15 mm – 0.18 mm); Copper Thickness(18µm / 35µm / 70µm); Min. Line / Spacing(50µm / 50µm); Max. PCB Size(580 mm x 500 mm); Smallest Drill(0.2 mm).

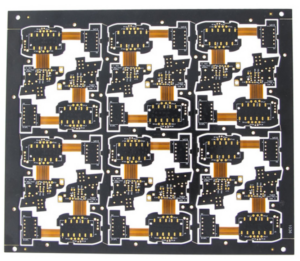

Rigid-Flexible PCBs

• Features — Free bending and flex resistance. Weight Reduction. High reliability and 3D Mounting. Printed circuit boards with rigid areas and flexible areas with reduced numbers of layers. Combination of polyimide and FR4, or FR4 and thin laminate. Rigid-flexible printed circuit boards which connect rigid boards without the need for cables or connectors, resulting in better signal transmission. With SMD population and underfill. All comonly used surfaces available.

• Competence — Structure(Multilayer Flexible Paging or Bonding Structure/HDI Structure); Layer(2-20);The Width of Minimum Flexible Zone(3mm); Line Width/Space(Inner:3/3mil,Outer:3.5/3.5mil); Minimum Drilling Diameter(0.10mm(Mechanical Drilling),0.15mm(Laser Drilling)); Minimum Ring Width(4mil); Spacing Between Hole abd Conductor(Layer≤6:5mil, 7≤Layer≤11:6mil, Layer≥12:8mil); Plate Thickness and Aperture Ratio(1:1(Blind Via);16:1(Through Via)); Dimension Accuracy(±0.1mm(specially±0.05mm)); Surface Processing Method(ENIG/ENEPIG/HASL/FLASH GOLD/HARD GOLD/OSP).

Flexible PCBs on Aluminium

• Features — Aluminium or copper heat sinks. Available with thermally conductive bonding material or prepreg (0.3-3.0 W/(m•K)). Available in punched version, or routed.

• Competence — Materials(Polyimide); Layer(Single Sided – 3 Layer); Thickness of The Finished Product(50µm – 1200µm (including Stiffner)); Copper Thickness(9µm / 12µm / 18µm / 35µm); Min. Line / Spacing(65µm / 65µm ( LDI )); Surfaces(OSP/ Immersion Tin / Immersion Ni / Au / Plated Ni/Au); Smallest Drill(0.2 mm).

Applications:

* Medical – Diagnostic hardware, medical electronics and medical imaging devices.

* Telecommunications – High frequency chip carriers and fiber-optic communication products.

* Industrial & Commercial – Robotics, consumer electronics and LED lighting applications.

* Automotive – Camera modules, lighting and other automotive electronics.