Before starting the design, MCU design manufacturers need to ask customers for some key information to ensure that the MCU design meets the customer’s needs and expectations.

Here are some suggested materials:

Demand specification

The customer should provide a detailed demand specification, including the functions, performance indicators, interface requirements, cost budget, etc. that the MCU needs to implement. MCU design manufacturers can use this manual to evaluate whether the customer’s needs are feasible and determine the design direction.

Application scenarios

Understanding customer application scenarios is very important for MCU design. For example, what type of equipment the MCU will be used in, what the working environment is like, what are the life and reliability requirements, etc. This information can help MCU design manufacturers choose the appropriate chip architecture and packaging form, and optimize the design solution.

Specifications or technical manuals

Customers should provide MCU specifications or technical manuals, including the chip’s pin definition, voltage range, temperature range, packaging form and other information. This information can help MCU design manufacturers better understand customer needs and determine whether the design solution meets the requirements.

Special requirements

Customers may have some special requirements, such as the need to use specific programming languages or development tools, or the need to implement specific functions or protocols. MCU design manufacturers need to understand these special requirements and consider how to meet these requirements in their design.

Certification requirements

If the customer’s equipment needs to comply with certain certification standards, such as CE, UL, etc., the customer should provide these certification requirements. MCU design manufacturers need to understand these requirements and consider how to meet these standards in their designs.

Production cycle and output

Customers should inform MCU design manufacturers of their production cycle and output plans. This will help MCU design manufacturers determine whether the design solution meets the needs of mass production and optimize the production process.

Cost budget

Customers should provide their cost budget, which will help MCU design manufacturers evaluate whether the design solution meets the customer’s budget requirements and optimize costs while meeting performance and functional requirements.

Development tools and software

Customers should provide information on the development tools and software they use, including compilers, debuggers, emulators, etc. This will help MCU design manufacturers provide development environments and software tools that better meet customer needs.

MCU upgrade strategy

Customers should inform MCU design manufacturers of their upgrade strategies, including performance improvements, function expansions, etc. that may be needed in the future. This will help MCU design manufacturers consider future upgrade and maintenance needs when designing.

Other relevant information

Depending on customer needs, customers may also need to provide other relevant information, such as market research reports, competitor analysis reports, etc. This information can help MCU design manufacturers better understand customer needs and market conditions, and provide more competitive design solutions.

In short, MCU design manufacturers need to ask customers for a lot of information. This information will help them better understand customer needs and expectations and provide design solutions that better meet customer needs. At the same time, this information can also help MCU design manufacturers evaluate whether the design solution is feasible, optimize the production process and reduce costs.

Microcontroller PCB board manufacturers in China

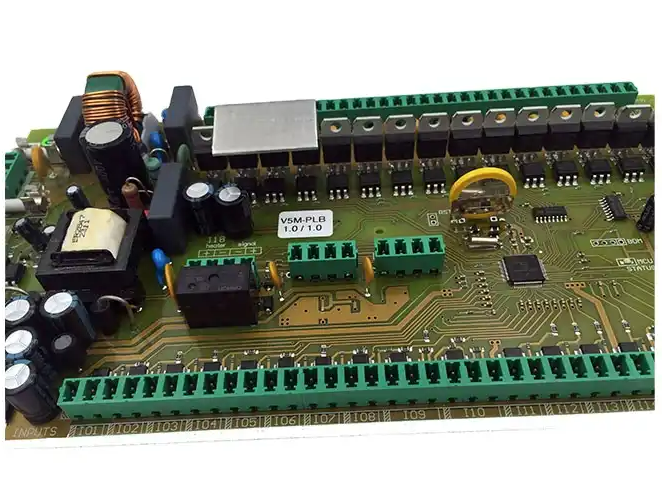

Microcontroller PCB board manufacturers refer to manufacturers that specialize in producing and manufacturing microcontroller PCB boards. These manufacturers usually have advanced production equipment and manufacturing technology and can provide high-quality, high-reliability microcontroller PCB boards.

The microcontroller PCB board is the core component of the microcontroller. It carries all the circuits and components of the microcontroller and ensures the stable operation of the microcontroller. Therefore, it is very important to choose a reliable microcontroller PCB board manufacturer.

Some well-known microcontroller PCB board manufacturers include Fumax, Shenzhen Grace, Zhuhai Yipin, Chengdu Yipin, etc. These manufacturers have professional R&D teams and production equipment, can carry out customized production according to customer needs, and provide complete technical support and after-sales service.

In short, choosing a reliable microcontroller PCB board manufacturer can provide a strong guarantee for the stable operation of the microcontroller, and can also improve the performance and reliability of the entire system.

Shenzhen Fumax Technology Co., Ltd. is a microcontroller electronic design manufacturer, focusing on the design, R&D and production of microcontrollers. Its business scope covers industrial control, home appliances, automotive electronics, Internet of Things and other fields, providing customers with a full range of microcontrollers Customized services.