Automotive motor drive PCB customization manufacturers focus on providing high-quality, high-reliability PCB boards for automotive motor drive systems.

They have a professional technical team and advanced production equipment, and can provide customized PCB board solutions according to customer needs and design requirements.

These manufacturers focus on technological innovation and product research and development, and constantly introduce new products that adapt to market needs to meet the different needs of customers. They are committed to providing customers with high-quality products and services to help ensure the stable operation of automotive motor drive systems.

Research on automotive motor drive PCB customization manufacturers

With the continuous development of automotive technology and the trend of electrification, motor drive technology has become a core component of modern vehicles.

Motor drive technology involves complex environments such as high voltage, high current, and high frequency, so the requirements for PCB boards are also very high. This article will discuss the research on automotive motor drive PCB customization manufacturers, with a view to providing reference for the development of related fields.

Overview of automotive motor drive PCB customization manufacturers

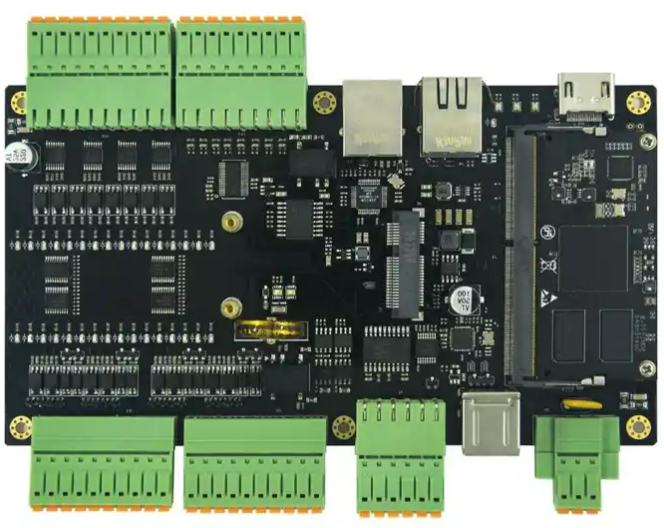

Automotive motor drive PCB customization manufacturers refer to manufacturers that specialize in providing customized PCB boards for automotive motor drive systems. These manufacturers usually have professional technical teams and advanced production equipment, and can provide high-quality, high-reliability PCB boards according to customer needs and design requirements.

Technical requirements for automotive motor drive PCB customization manufacturers

- High reliability: Automotive motor drive systems involve complex environments such as high voltage, large current, and high frequency, so the requirements for PCB boards are very high. PCB boards need to have high reliability and be able to withstand harsh working environments to ensure the stability and reliability of the system.

- High temperature resistance: The working temperature of the automobile motor drive system is relatively high, so the PCB board needs to have high temperature resistance and be able to withstand the working requirements in high temperature environments.

- Electromagnetic compatibility: The automobile motor drive system involves electromagnetic interference issues, so the PCB board needs to have good electromagnetic compatibility, which can effectively suppress electromagnetic interference and ensure the normal operation of the system.

- Automated production: In order to meet the needs of mass production, automotive motor drive PCB customization manufacturers need to have the ability to automate production to improve production efficiency and quality.

Production process of automobile motor drive PCB customization manufacturer

- Design stage: Design the PCB board according to the customer’s needs and design requirements. During the design process, factors such as circuit layout, wiring rules, and component packaging need to be considered to ensure the rationality and reliability of the design.

- Board making stage: Make boards according to design drawings, including selecting appropriate materials, processing techniques and production equipment. Quality monitoring and inspection need to be paid attention to during the board making process to ensure the accuracy and reliability of board making.

- Welding stage: Weld the components to the PCB board to ensure welding quality and reliability. During the welding process, attention needs to be paid to the control of the welding process and welding temperature to avoid problems such as virtual welding and cold welding.

- Testing stage: Test the welded PCB board, including functional testing, performance testing and reliability testing. During the testing process, attention must be paid to the recording and analysis of test methods and test data to ensure the accuracy and reliability of the test.

- Assembly stage: Assemble the tested PCB board into the motor drive system to ensure the quality and reliability of the assembly. During the assembly process, attention needs to be paid to the control of the assembly process and assembly sequence to avoid problems such as misassembly and missing assembly.

- Delivery stage: Deliver the assembled motor drive system to the customer, providing complete delivery documents and technical support. During the delivery process, attention needs to be paid to the control of delivery quality and delivery time to ensure the accuracy and timeliness of delivery.

Advantages of automotive motor drive PCB customization manufacturers

- Strong professionalism: Automotive motor drive PCB customization manufacturers usually have professional technical teams and advanced production equipment, and can provide customers with high-quality, high-reliability PCB boards.

- Customized services: Automotive motor drive PCB customization manufacturers can provide customized PCB board services according to customer needs and design requirements to meet customers’ special needs.

- High production efficiency: Automotive motor drive PCB customization manufacturers usually have the ability to automate production, which can improve production efficiency and quality and meet the needs of mass production.

- Good after-sales service: Automotive motor drive PCB customization manufacturers usually provide complete after-sales service and technical support, and can provide customers with a full range of services and support.

Conclusion and Outlook

This article discusses the research on automotive motor drive PCB customization manufacturers, including technical requirements, production processes and advantages. With the continuous development of automotive technology and the trend of electrification, automotive motor drive PCB customization manufacturers will play an increasingly important role. In the future, with the continuous advancement of technology and changing market demands, automotive motor drive PCB customization manufacturers need to continue to innovate and develop, improve their technical level and production capacity, and provide customers with better services and support.