Outdoor LED lamp PCB assembly technical services are a series of technical services provided for PCB board assembly of outdoor LED lamps.

These services include PCB board design, manufacturing, assembly and testing to ensure that outdoor LED lamps can withstand harsh environmental conditions and have efficient and reliable lighting performance.

The following is a detailed introduction to outdoor LED light PCB assembly technical services:

PCB board design

The PCB board design of outdoor LED lights needs to take into account many factors, such as weather resistance, heat dissipation performance, electrical performance, etc. Designers need to select appropriate materials and processes based on the usage environment and functional requirements of the lamps to ensure the stability and reliability of the PCB board. At the same time, designers also need to carry out reasonable wiring design and component layout to ensure the electrical performance and heat dissipation performance of the lamps.

PCB board manufacturing

The PCB board manufacturing of outdoor LED lights requires the use of high-quality materials and advanced processes to ensure good weather resistance and electrical performance. Quality inspection and control are required during the manufacturing process to ensure that each PCB board meets design requirements and quality standards.

Component procurement and testing

The components of outdoor LED lights need to be waterproof, dustproof, and high temperature resistant to ensure that they can work normally under harsh environmental conditions. Procurement personnel need to choose reliable suppliers and brands to ensure the quality and reliability of components. At the same time, quality inspection and control are required after the components arrive to ensure that each component meets the requirements.

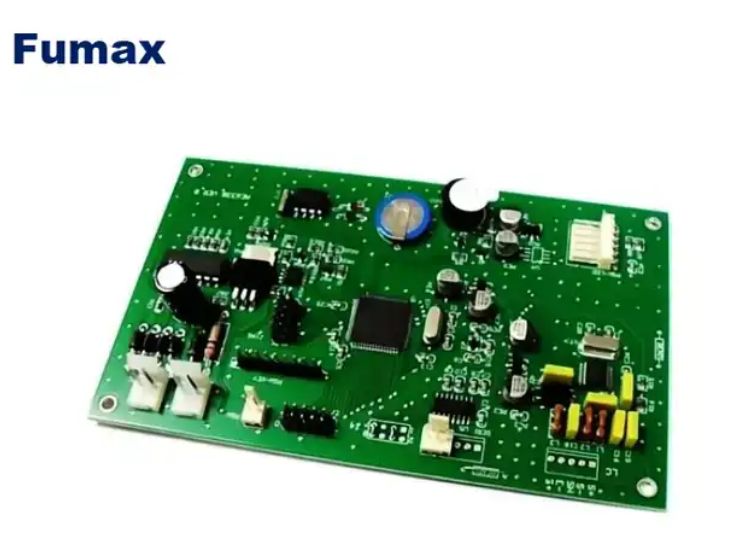

PCB board assembly

PCB board assembly of outdoor LED lights requires the use of advanced processes and technologies to ensure assembly accuracy and reliability. Quality inspection and control are required during the assembly process to ensure that every assembly link meets the requirements. At the same time, functional testing and debugging are also required to ensure the normal function and stable performance of the lamps.

Packaging and shipping

The packaging of outdoor LED lights needs to take into account shockproof, waterproof, dustproof and other requirements to ensure that they will not be damaged during transportation. Packaging materials need to have corresponding protective properties and pressure resistance to ensure the safety of lamps during transportation and storage. At the same time, customized packaging design and production also need to be carried out according to customer requirements.

Technical training and support

In order to ensure that customers can correctly use and maintain outdoor LED lighting fixtures, suppliers need to provide corresponding technical training and support services.

The training content includes the use, maintenance, and handling of common problems of lamps, etc., to ensure that customers can receive timely technical support and solutions during use.

At the same time, suppliers also need to provide long-term after-sales service and technical support to meet the problems and needs customers encounter during use.

In short, outdoor LED light PCB assembly technical services need to take into account quality control and technical support in all aspects from design to production, assembly, testing, packaging and transportation.

Only suppliers with professional skills and rich experience can provide high-quality outdoor LED lighting fixtures and services to meet customer needs and requirements. Choosing a reliable supplier is one of the key factors in ensuring the quality and reliability of outdoor LED lighting fixtures.